NEWS EVENTS

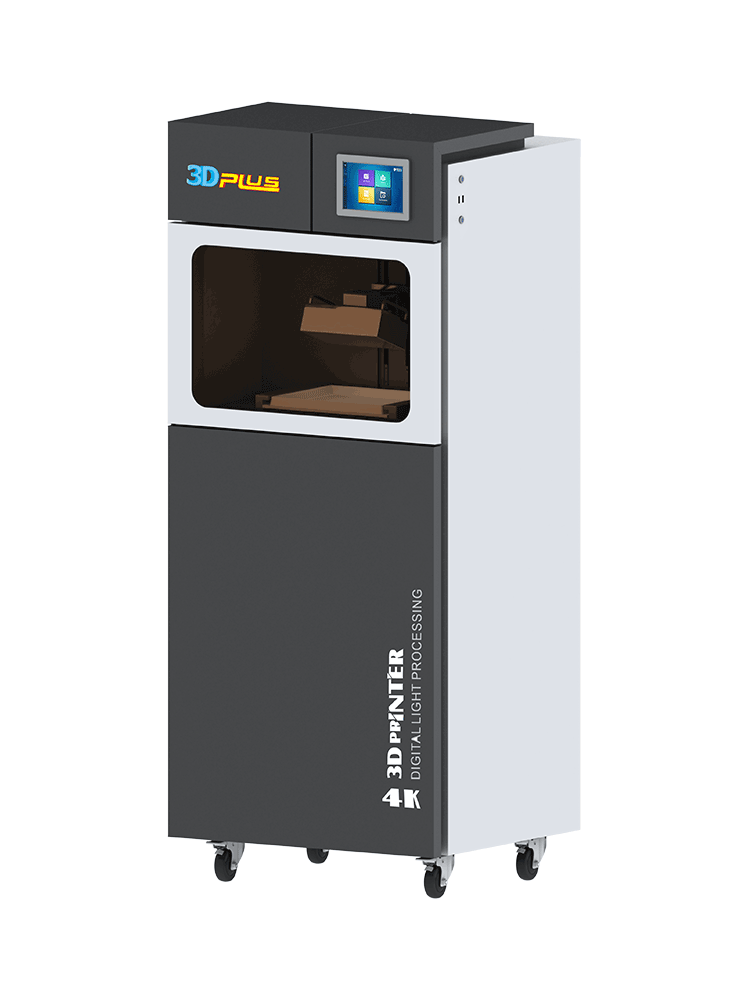

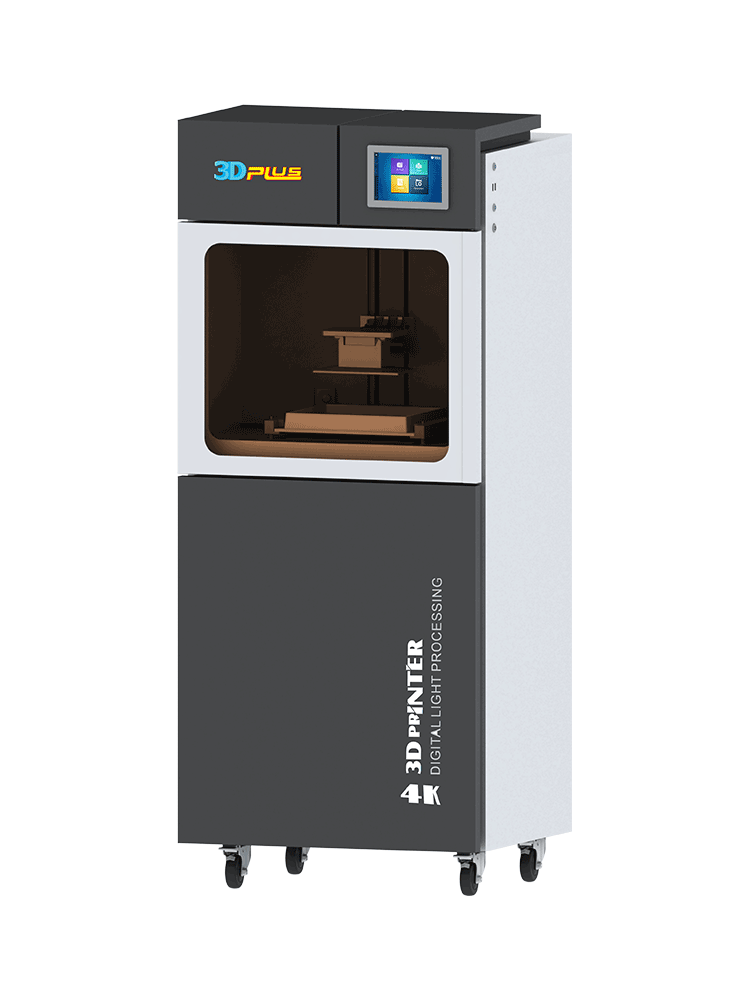

Enhancing Efficiency and Precision with Industrial Toy DLP 3D Printer: Revolutionizing Production Processes

2025-04-28

Enhancing Efficiency and Precision with Industrial Toy DLP 3D Printer

Table of Contents

- 1. Introduction to Industrial Toy DLP 3D Printer

- 2. What is DLP Technology?

- 3. Advantages of DLP 3D Printing for Businesses

- 4. Applications of Industrial Toy DLP Printers

- 5. How to Choose the Right DLP Printer for Your Needs

- 6. Maintenance and Care for DLP Printers

- 7. The Future of DLP 3D Printing in Manufacturing

- 8. Conclusion

1. Introduction to Industrial Toy DLP 3D Printer

The **Industrial Toy DLP 3D Printer** is at the forefront of a manufacturing revolution. As industries seek to streamline production processes, improve product quality, and reduce costs, this advanced technology emerges as a crucial solution. Unlike traditional 3D printing methods, DLP (Digital Light Processing) technology leverages light to cure liquid resin into solid objects, significantly enhancing the precision and efficiency of the printing process. In this article, we delve into the benefits, applications, and future potential of Industrial Toy DLP 3D Printers.

2. What is DLP Technology?

DLP technology is a form of 3D printing that utilizes a digital light projector to selectively cure photopolymer resin into solid structures. This method works by projecting an entire layer of the object at once, rather than painstakingly building it up layer by layer, as seen in traditional FDM (Fused Deposition Modeling) printers.

How DLP Technology Works

The process begins with a vat of liquid resin. A digital light source, typically a high-resolution projector, emits light to cure the resin in specific areas, forming a solid layer. After each layer is completed, the build platform lowers slightly, allowing for the next layer to be cured. This layer-by-layer approach continues until the entire object is complete.

Key Features of DLP Technology

- **Speed**: DLP printers can produce parts faster than traditional methods due to their layer-wide curing technique.

- **Precision**: The high resolution of DLP printing allows for intricate details and smooth surface finishes, making it ideal for applications requiring accuracy.

- **Material Flexibility**: DLP printers can work with a variety of photopolymers, allowing for different properties and finishes.

3. Advantages of DLP 3D Printing for Businesses

Businesses looking to enhance their production capabilities can benefit from DLP 3D printing in several ways:

Increased Production Efficiency

DLP 3D printers can produce complex designs in a fraction of the time required by traditional methods. This time efficiency allows companies to meet tight deadlines and respond swiftly to market demands.

Cost-Effectiveness

By reducing waste material and minimizing the need for secondary finishing processes, DLP printing lowers costs. Furthermore, companies can create prototypes quickly, allowing for iterative testing and reduced time to market.

High Precision and Quality

The ability to achieve fine details and smooth finishes makes DLP printing suitable for industries like jewelry, dental, and aerospace, where precision is paramount.

Reduced Material Waste

DLP printers use liquid resin that is cured only where needed, which reduces material wastage compared to traditional subtractive manufacturing methods.

4. Applications of Industrial Toy DLP Printers

Industrial Toy DLP Printers are versatile tools with applications across various industries:

1. Prototyping

Designers and engineers can create prototypes quickly and accurately, allowing for rapid testing and feedback before moving to full-scale production.

2. Medical Devices and Implants

The precision of DLP printing is ideal for creating custom medical devices and implants tailored to individual patient needs.

3. Jewelry Design

Jewelry makers can produce intricate designs with fine details, enhancing the aesthetic appeal of their products.

4. Automotive Parts

DLP printers can manufacture complex automotive components, reducing weight and improving performance.

5. Architectural Models

Architects can create detailed scale models that accurately represent their designs, facilitating better communication with clients and stakeholders.

5. How to Choose the Right DLP Printer for Your Needs

Selecting the appropriate DLP printer involves considering several factors:

1. Build Volume

Evaluate the size of the parts you intend to print. Make sure the printer's build volume accommodates your requirements.

2. Resolution

Higher resolution printers provide finer details. Determine the level of detail necessary for your projects and select accordingly.

3. Material Compatibility

Check the range of materials the printer supports. Ensure it can work with the resins suited to your specific applications.

4. User Interface and Software

A user-friendly interface and compatible software can significantly enhance the printing experience. Look for printers that offer easy navigation and strong support for slicing software.

5. Budget

While advanced DLP printers can be an investment, consider the long-term savings and benefits they provide. Assess your budget against the anticipated return on investment.

6. Maintenance and Care for DLP Printers

Proper maintenance is essential for ensuring longevity and optimal performance of your DLP printer:

1. Regular Cleaning

Keep the resin vat and build platform clean to prevent contamination and ensure print quality. Use appropriate cleaning solutions for resin.

2. Calibration

Periodically calibrate your printer to maintain accuracy. Follow manufacturer guidelines for calibration procedures.

3. Software Updates

Keep the printer firmware and slicing software updated to benefit from the latest features and improvements.

4. Store Resin Properly

Store unused resin in a cool, dark place to prevent degradation and ensure print quality.

7. The Future of DLP 3D Printing in Manufacturing

As technology continues to evolve, so too does the potential for DLP 3D printing. The future holds exciting possibilities, including:

1. Enhanced Materials

Advancements in photopolymer materials will expand the applications of DLP printing, allowing for stronger, lighter, and more flexible products.

2. Integration with Other Technologies

Combining DLP printing with other manufacturing processes, such as CNC machining or traditional injection molding, could improve efficiency and product offerings.

3. Automation and AI

The incorporation of automation and artificial intelligence will streamline workflows and enhance the capabilities of DLP printers, enabling smarter production environments.

4. Sustainability

As industries shift towards more sustainable practices, DLP printing is poised to become a key player in reducing waste and promoting eco-friendly materials.

8. Conclusion

The **Industrial Toy DLP 3D Printer** is reshaping the landscape of manufacturing, enhancing efficiency and precision across multiple industries. Its rapid production capabilities, high-quality outputs, and versatility make it an indispensable tool for businesses aiming to stay competitive in a fast-paced market. By understanding the technology, benefits, and applications of DLP printing, organizations can harness its potential to drive innovation and improve their production processes. Embracing this technology today positions businesses for a successful and sustainable future.

FAQs

1. What is the primary difference between DLP and FDM printing?

DLP printing uses a light source to cure liquid resin, producing layers simultaneously, while FDM printing extrudes thermoplastic filament layer by layer.

2. How long does it take to print an object using a DLP printer?

Print times vary based on the size and complexity of the object. However, DLP printers can produce parts significantly faster compared to traditional methods.

3. What types of materials can be used in DLP printers?

DLP printers are compatible with various photopolymer resins, including standard, flexible, and high-temperature materials.

4. Are DLP printers suitable for mass production?

While DLP printers excel in rapid prototyping and small batch production, advancements in speed and material capabilities are making them increasingly viable for mass production.

5. How do I maintain a DLP printer?

Regular cleaning, calibration, and proper storage of resin are essential for maintaining optimal performance and extending the printer's lifespan.

Keywords: Industrial Toy DLP 3D Printer

Related News

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262