NEWS EVENTS

Innovative Technology: Exploring the World of DLP 3D Printed Jewelry

2025-06-09

Innovative Technology: Exploring the World of DLP 3D Printed Jewelry

Table of Contents

- 1. Introduction to DLP 3D Printed Jewelry

- 2. What is DLP 3D Printing?

- 3. Advantages of DLP 3D Printing in Jewelry

- 4. Applications of DLP 3D Printed Jewelry

- 5. The DLP 3D Jewelry Design Process

- 6. Material Options for DLP 3D Printing

- 7. Future Trends in DLP 3D Printed Jewelry

- 8. Conclusion

- 9. FAQs

1. Introduction to DLP 3D Printed Jewelry

The world of jewelry has undergone a remarkable transformation with the introduction of **Digital Light Processing (DLP) 3D printing technology**. This innovative approach allows designers to create intricate and unique pieces that cater to individual tastes while minimizing manufacturing costs and time. By merging artistry with technology, DLP 3D printing has positioned itself as a revolutionary tool in the jewelry-making industry.

In this article, we will explore the various aspects of DLP 3D printed jewelry, including its definition, advantages, applications, and future trends. By the end, you will have a comprehensive understanding of how this technology is reshaping the jewelry landscape.

2. What is DLP 3D Printing?

**Digital Light Processing (DLP)** is a technology that utilizes digital projectors to cure photopolymer resin and create three-dimensional objects layer by layer. DLP printers project light through a digital micromirror device (DMD), which selectively illuminates the resin to solidify it in precise patterns. This process enables incredibly detailed creations and faster printing speeds compared to traditional 3D printing methods.

DLP technology is particularly advantageous for jewelry designers who require precision and detail in their work. The ability to produce complex geometries and intricate designs makes DLP an ideal choice for crafting unique jewelry pieces.

3. Advantages of DLP 3D Printing in Jewelry

DLP 3D printing offers numerous advantages that make it a preferred choice for jewelry designers:

3.1 Enhanced Detail and Precision

DLP technology allows for the creation of highly detailed designs that traditional methods struggle to replicate. The precision of DLP printing ensures that every nuance of a jewelry piece is captured, resulting in stunning final products.

3.2 Faster Production Times

With DLP, multiple pieces can be printed simultaneously, significantly reducing production time. This efficiency allows designers to respond quickly to market demands and customize pieces for individual clients.

3.3 Cost-Effectiveness

DLP printing minimizes material waste and reduces labor costs, making it a cost-effective option for both small and large-scale production. The ability to create molds from 3D printed models further lowers costs in the manufacturing process.

3.4 Customization and Personalization

One of the most significant advantages of DLP 3D printing is the ease of customization. Designers can create bespoke pieces tailored to the unique preferences of their clients, fostering a personalized experience that resonates with consumers.

3.5 Sustainability

DLP 3D printing is generally more sustainable than traditional jewelry manufacturing methods. The reduction in material waste and the possibility of using eco-friendly resins contribute to a more environmentally friendly approach to jewelry design.

4. Applications of DLP 3D Printed Jewelry

DLP 3D printing is revolutionizing various applications within the jewelry industry, including:

4.1 Prototyping and Design Testing

Designers can quickly create prototypes to test and refine their concepts before committing to full production. This iterative process enhances creativity and innovation in jewelry design.

4.2 Custom Jewelry Creation

DLP technology enables jewelers to offer custom pieces that cater to individual tastes. Whether it’s a unique engagement ring or a personalized charm, DLP printing makes it possible to bring any vision to life.

4.3 Production of Molds for Casting

Jewelry makers can use DLP 3D printed models to create silicone molds for casting. This method allows for the accurate replication of designs and facilitates mass production with consistent quality.

4.4 Complex Geometries

Designers can explore intricate patterns and complex geometries that were previously difficult to achieve. DLP printing empowers jewelers to push the boundaries of traditional design.

4.5 Collaboration with Artists

DLP technology fosters collaboration between jewelers and artists, allowing for the blending of various styles and techniques. This cross-pollination can lead to innovative and unexpected jewelry pieces.

5. The DLP 3D Jewelry Design Process

Creating DLP 3D printed jewelry involves several critical steps:

5.1 Concept Development

The process begins with brainstorming and sketching ideas. Designers consider elements such as form, function, and the target audience.

5.2 3D Modeling

Using specialized design software, the concept is transformed into a digital 3D model. This stage requires attention to detail to ensure accuracy in the final product.

5.3 Preparing for Printing

The 3D model is sliced into layers, and parameters such as resin type and print speed are set. This preparation is crucial for achieving the desired quality.

5.4 Printing

The DLP printer projects light onto the resin, solidifying it layer by layer until the complete piece is formed. This stage is where the magic happens, turning digital designs into tangible objects.

5.5 Post-Processing

Once printed, the jewelry undergoes cleaning and curing to ensure durability. Additional finishing techniques, such as polishing or coating, may be applied to enhance the final appearance.

6. Material Options for DLP 3D Printing

The choice of materials plays a pivotal role in the quality and appeal of DLP 3D printed jewelry. Commonly used materials include:

6.1 Photopolymer Resins

These resins are specifically formulated for DLP printing and come in various colors and finishes. They offer excellent detail and can mimic the appearance of precious metals.

6.2 Metal Alloys

Some advancements in DLP technology allow for the printing of metal jewelry, offering durability and a premium look. Metal alloys can be used to create pieces that maintain the charm of traditional jewelry.

6.3 Biocompatible Materials

For jewelry intended for sensitive skin, biocompatible resins are available. These materials ensure safety and comfort for the wearer, making them ideal for earrings and other body adornments.

6.4 Eco-Friendly Resins

As sustainability becomes a priority, eco-friendly resins are gaining popularity. These materials are designed to minimize environmental impact while still providing the quality needed for high-end jewelry.

7. Future Trends in DLP 3D Printed Jewelry

The landscape of DLP 3D printed jewelry is evolving rapidly, with emerging trends that promise to reshape the industry:

7.1 Integration of Smart Technology

The incorporation of smart technology into jewelry is on the rise. From health-tracking rings to customizable wearable devices, the fusion of fashion and technology is creating exciting possibilities.

7.2 Enhanced Customization Options

As DLP technology continues to advance, the level of customization will become even more sophisticated. Consumers will have greater control over design elements, materials, and finishes.

7.3 Collaborative Design Platforms

Online platforms that allow for collaborative design among users and designers are emerging. This democratization of design will lead to unique, crowd-sourced jewelry pieces that reflect diverse tastes and styles.

7.4 Sustainable Practices

The jewelry industry is increasingly focusing on sustainable practices. DLP 3D printing aligns with this trend, as it reduces waste and encourages the use of sustainable materials in production.

8. FAQs

8.1 What is the difference between DLP and SLA 3D printing?

DLP (Digital Light Processing) uses a digital projector to cure resin, while SLA (Stereolithography) employs a laser. DLP generally offers faster print speeds and can produce high-quality details.

8.2 Can DLP 3D printed jewelry be resized?

In most cases, DLP 3D printed jewelry can be resized, although it may require additional work by a jeweler to maintain the design's integrity.

8.3 How durable is DLP 3D printed jewelry?

DLP 3D printed jewelry can be quite durable, especially when post-processed correctly. The choice of materials also plays a significant role in the final product's durability.

8.4 Is DLP 3D printed jewelry hypoallergenic?

Many DLP 3D printing materials are hypoallergenic, but it's essential to verify the specific resins used, especially for sensitive skin.

8.5 What types of jewelry can be made using DLP technology?

DLP technology can be used to create various types of jewelry, including rings, earrings, pendants, bracelets, and more, with incredible detail and customization options.

9. Conclusion

DLP 3D printed jewelry represents a significant milestone in the fusion of technology and artistry. By providing designers with unparalleled precision, speed, and customization capabilities, this innovative approach is setting new standards in the jewelry industry. As we look toward the future, the integration of smart technology, sustainable practices, and collaborative design will undoubtedly enhance the evolution of DLP 3D printed jewelry, making it an exciting area to watch. Whether you're a jewelry maker or an enthusiast, embracing this revolutionary technology opens doors to endless creative possibilities.

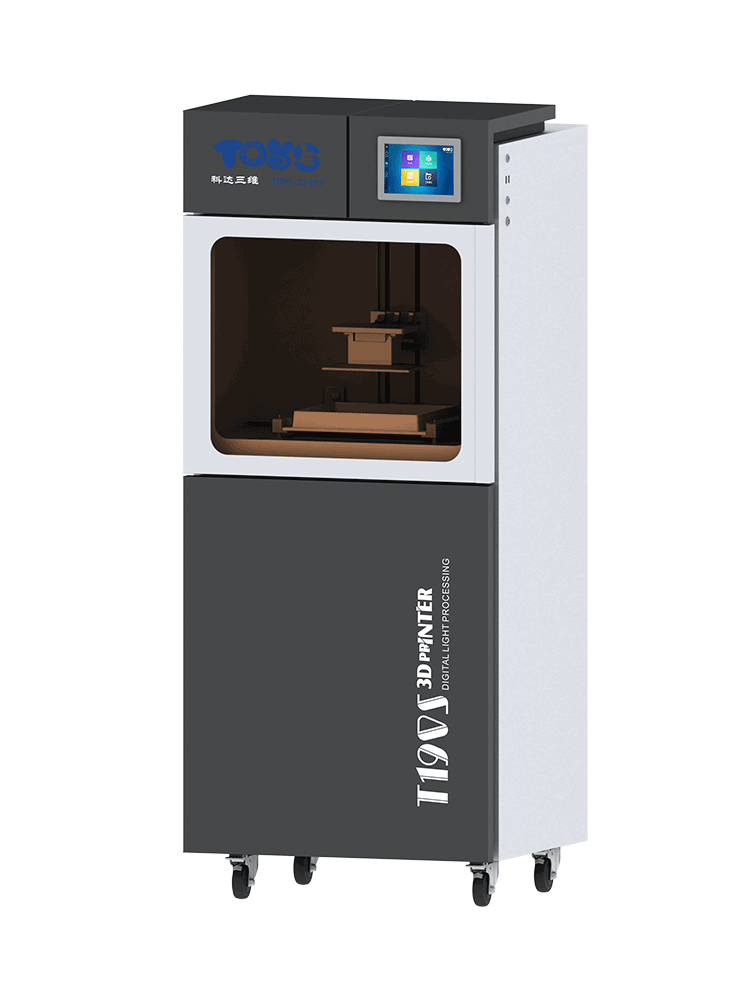

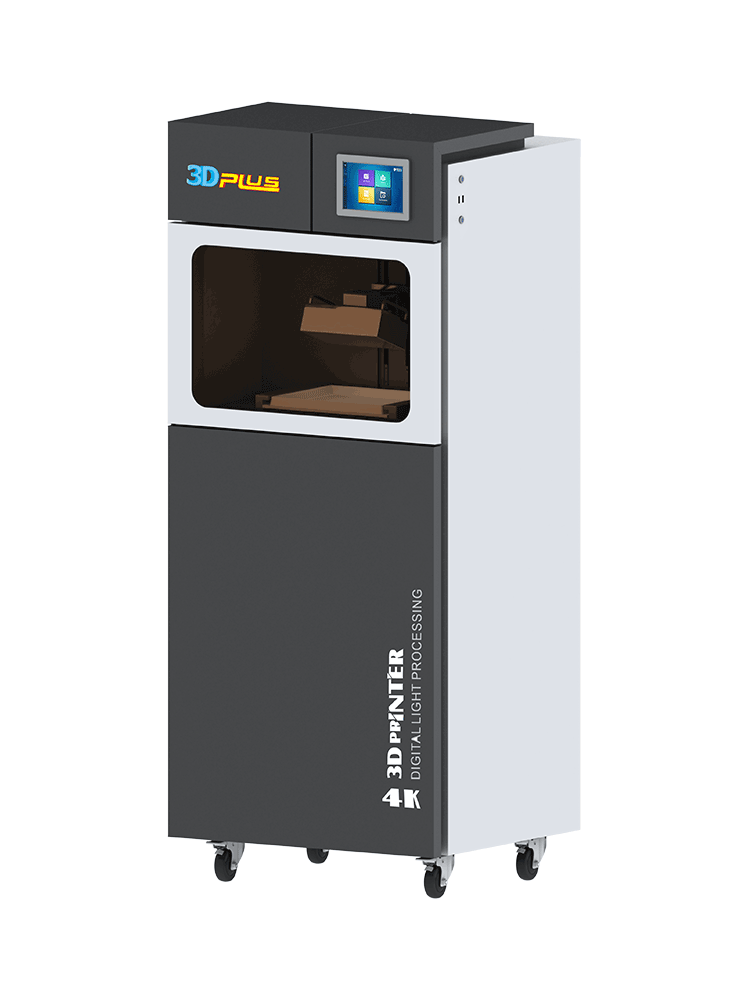

Keywords: Jewelry DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262