NEWS EVENTS

Unlocking Possibilities: The Power of Industrial Toy DLP 3D Printers

2025-08-11

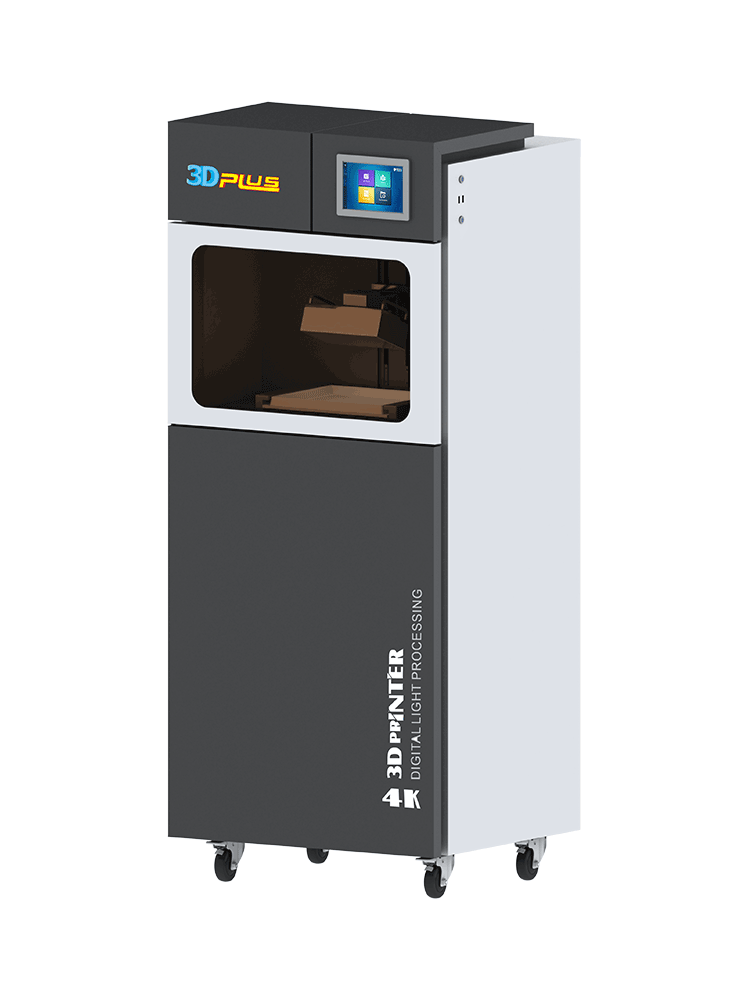

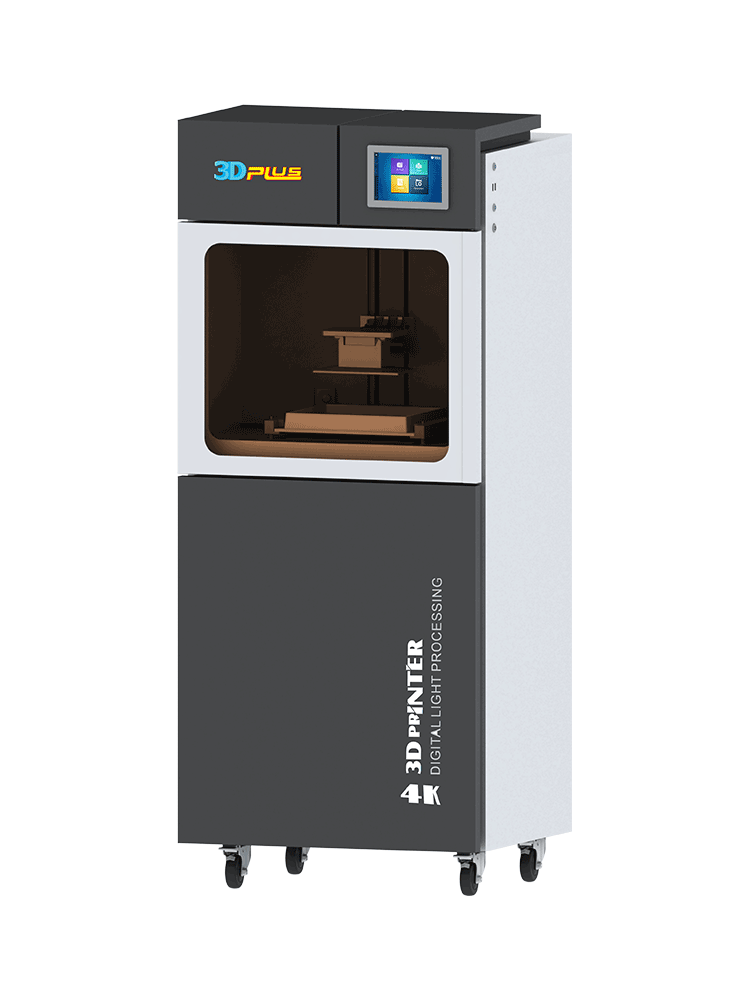

The Industrial Toy DLP 3D Printer represents a significant advancement in 3D printing technology, particularly for professionals in the consumer electronics and cultural office equipment industries. Utilizing Digital Light Processing (DLP) technology, these printers employ a digital light source to cure resin layer by layer, resulting in high-quality and precise 3D models. This method of printing is particularly beneficial for producing intricate designs and prototypes, making it a preferred choice for various applications.

One of the key advantages of Industrial Toy DLP 3D Printers is their ability to achieve exceptional resolution. The DLP technology allows for detailed prints with smooth finishes, which is critical for industries that require accuracy and precision, such as product design and crafting. The layer thickness can often be adjusted, providing flexibility in selecting the detail level and print speed. This makes DLP printers suitable for both rapid prototyping and full-scale production.

Another notable feature of these printers is their efficiency. DLP printers can create multiple parts simultaneously due to their layer-by-layer approach, significantly reducing production time compared to traditional methods. This efficiency is especially valuable for businesses that need to meet tight deadlines while maintaining high-quality standards.

Moreover, Industrial Toy DLP 3D Printers offer a variety of materials for printing, including different types of resins that cater to specific needs, such as flexibility, durability, or aesthetic appeal. This versatility enables designers and manufacturers to experiment with new ideas and innovate their product offerings. The ability to print in various materials also means that these printers can be used for a wide range of applications, from functional prototypes to artistic creations.

In addition to their technical capabilities, Industrial Toy DLP 3D Printers are often designed with user-friendliness in mind. Many models come equipped with intuitive software that simplifies the design-to-print process, making it easier for professionals to bring their ideas to life without extensive technical knowledge. This accessibility is an essential factor for businesses looking to integrate 3D printing into their workflow.

Lastly, as industries continue to embrace digital manufacturing technologies, the role of Industrial Toy DLP 3D Printers is becoming increasingly crucial. They not only enhance productivity and creativity but also provide a sustainable alternative to traditional manufacturing methods. By reducing material waste and enabling on-demand production, these printers align with the growing emphasis on sustainable practices in manufacturing.

In conclusion, the Industrial Toy DLP 3D Printer is a powerful asset in the consumer electronics landscape, offering unmatched quality, efficiency, and versatility. As businesses seek to innovate and streamline their processes, embracing this technology can lead to significant advancements in product development and design.

One of the key advantages of Industrial Toy DLP 3D Printers is their ability to achieve exceptional resolution. The DLP technology allows for detailed prints with smooth finishes, which is critical for industries that require accuracy and precision, such as product design and crafting. The layer thickness can often be adjusted, providing flexibility in selecting the detail level and print speed. This makes DLP printers suitable for both rapid prototyping and full-scale production.

Another notable feature of these printers is their efficiency. DLP printers can create multiple parts simultaneously due to their layer-by-layer approach, significantly reducing production time compared to traditional methods. This efficiency is especially valuable for businesses that need to meet tight deadlines while maintaining high-quality standards.

Moreover, Industrial Toy DLP 3D Printers offer a variety of materials for printing, including different types of resins that cater to specific needs, such as flexibility, durability, or aesthetic appeal. This versatility enables designers and manufacturers to experiment with new ideas and innovate their product offerings. The ability to print in various materials also means that these printers can be used for a wide range of applications, from functional prototypes to artistic creations.

In addition to their technical capabilities, Industrial Toy DLP 3D Printers are often designed with user-friendliness in mind. Many models come equipped with intuitive software that simplifies the design-to-print process, making it easier for professionals to bring their ideas to life without extensive technical knowledge. This accessibility is an essential factor for businesses looking to integrate 3D printing into their workflow.

Lastly, as industries continue to embrace digital manufacturing technologies, the role of Industrial Toy DLP 3D Printers is becoming increasingly crucial. They not only enhance productivity and creativity but also provide a sustainable alternative to traditional manufacturing methods. By reducing material waste and enabling on-demand production, these printers align with the growing emphasis on sustainable practices in manufacturing.

In conclusion, the Industrial Toy DLP 3D Printer is a powerful asset in the consumer electronics landscape, offering unmatched quality, efficiency, and versatility. As businesses seek to innovate and streamline their processes, embracing this technology can lead to significant advancements in product development and design.

Keywords: Industrial Toy DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262