NEWS EVENTS

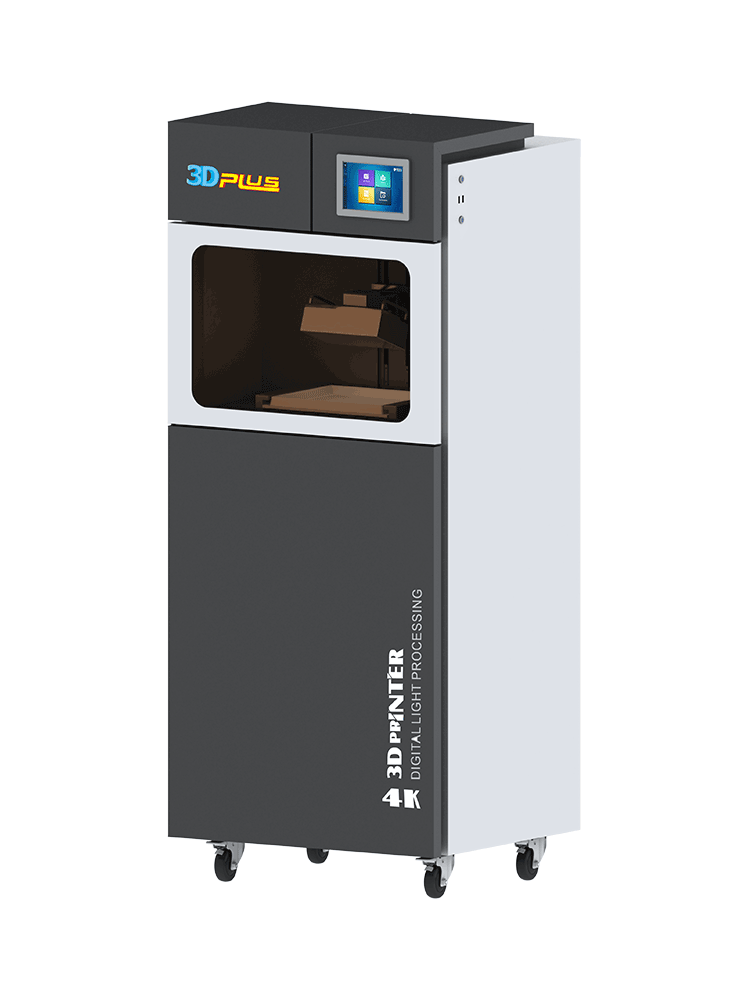

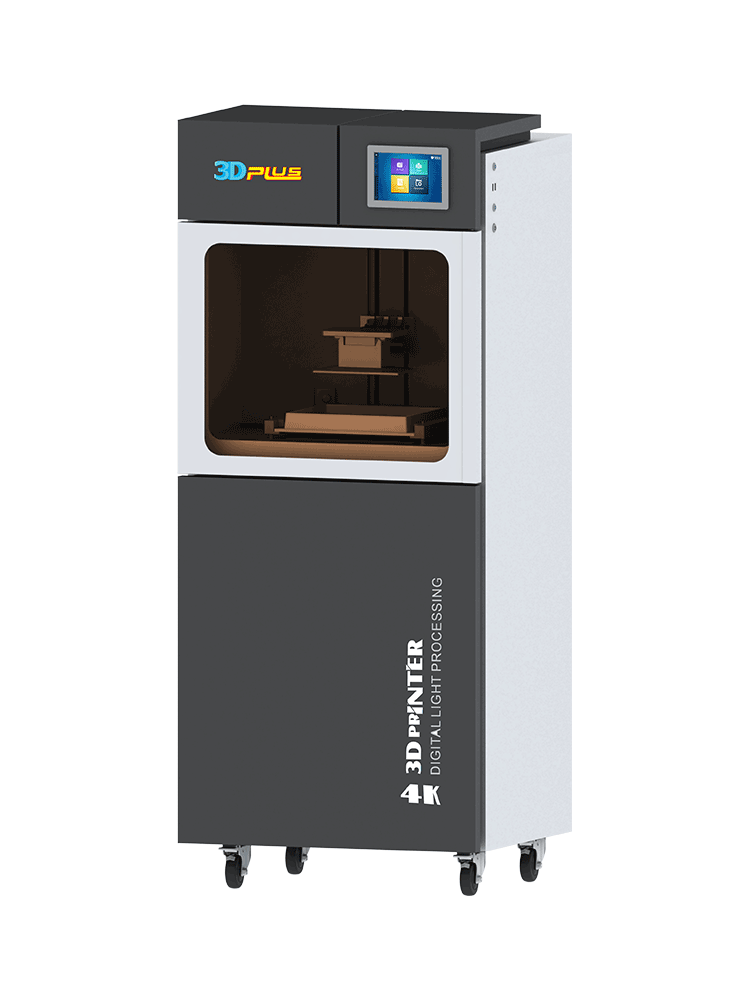

Elevate Your Printing Experience with Cutting-Edge Industrial Toy DLP Technology

2025-09-15

Elevate Your Printing Experience with Industrial Toy DLP Technology

In the rapidly evolving world of printing technologies, Industrial Toy DLP (Digital Light Processing) stands out as a remarkable innovation. This technology not only enhances the quality of prints but also optimizes the efficiency of the entire printing process. With an array of applications ranging from professional design to everyday printing needs, DLP technology is transforming how we approach printing. In this article, we will explore the intricacies of Industrial Toy DLP technology, its benefits, applications, and how it can elevate your overall printing experience.

Table of Contents

- What is DLP Technology?

- Advantages of DLP Printing Technology

- Applications of Industrial Toy DLP Technology

- How DLP Technology Works

- Choosing the Right DLP Printer for Your Needs

- Cost Effectiveness and Efficiency of DLP Printing

- DIY Projects with DLP Technology

- The Future of DLP Printing Technology

- Frequently Asked Questions

What is DLP Technology?

DLP technology, originally developed for projectors, uses a digital micromirror device (DMD) to create images by reflecting light. In the context of printing, Industrial Toy DLP takes this concept further by utilizing a light source—usually a high-intensity LED—to cure resin layer by layer. This process allows for incredibly fine details and smooth surfaces, making it particularly popular in fields where precision is paramount, such as jewelry design and prototyping.

Advantages of DLP Printing Technology

Unmatched Precision and Detail

One of the most significant advantages of DLP printing is its ability to produce highly detailed prints. The DMD chip allows for precise control over each individual pixel, resulting in sharp edges and intricate designs that traditional printing methods can struggle to achieve.

Fast Printing Speeds

Compared to other 3D printing technologies, DLP printers can produce items significantly faster. Since they cure an entire layer at once rather than point by point, DLP technology dramatically reduces printing times without sacrificing quality.

Enhanced Color Range

Industrial Toy DLP printers are capable of producing vibrant colors and gradients, thanks to their advanced light projection methods. This feature makes them ideal for applications where color accuracy is crucial, such as product prototypes and artistic prints.

Applications of Industrial Toy DLP Technology

Prototyping and Product Design

In the realm of product design, DLP technology has become indispensable. Designers can quickly create prototypes that are not only visually accurate but functional as well. This rapid prototyping capability accelerates the development cycle, allowing companies to bring products to market faster.

Jewelry and Fashion

The jewelry industry has embraced DLP technology due to its ability to produce intricate designs with high precision. From rings to intricate pendants, DLP printers can deliver pieces that are ready for casting or direct sale. Fashion designers are also utilizing this technology to create unique embellishments and accessories.

Medical Applications

In the medical field, DLP printing is revolutionizing the production of custom prosthetics, dental models, and surgical guides. The precision of DLP technology allows for personalized solutions tailored to individual patient needs, enhancing both the effectiveness and comfort of medical devices.

How DLP Technology Works

Understanding the mechanics of DLP technology helps in appreciating its efficiency. The process begins with a digital 3D model. The printer slices this model into thin layers, which are projected one layer at a time onto a vat of liquid resin.

Layer Curing Process

Once a layer is projected, the light cures the resin, hardening it into a solid form. The platform then lowers slightly, and the next layer is projected. This continues until the entire object is complete. The result is a robust and accurate 3D print with excellent surface quality.

Post-Processing

After printing, the object typically requires some post-processing, which may involve washing off excess resin and curing under UV light for added strength. Proper post-processing is essential for ensuring the longevity and durability of the print.

Choosing the Right DLP Printer for Your Needs

When selecting a DLP printer, consider several factors to ensure it meets your specific requirements:

Print Volume

Evaluate the size of the objects you intend to print. Different DLP printers offer varying build sizes, which can impact your capabilities.

Resolution

Look for a printer that offers high resolution for fine detail. The quality of the lens and the DMD chip plays a crucial role in the print resolution.

Material Compatibility

Ensure that the printer is compatible with a wide range of resins, including specialty materials for specific applications, such as flexible or heat-resistant resins.

Cost Effectiveness and Efficiency of DLP Printing

While the initial investment in DLP technology may seem high, its long-term cost efficiency is significant. The speed of printing reduces labor costs, while the precision minimizes material waste. Additionally, the durability of the prints often translates into lower replacement costs over time.

DIY Projects with DLP Technology

For hobbyists and DIY enthusiasts, DLP technology opens up a world of creativity. Here are some engaging projects to consider:

Custom Figurines and Models

Create personalized figurines for gifts or personal collections. The intricate detail achievable with DLP printing makes these projects rewarding and fun.

Home Decor Items

Design unique home decor pieces, from lampshades to wall art. With DLP technology, you can experiment with different designs and colors.

Functional Objects

Print custom tools, gadgets, or household items tailored to your specific needs. The versatility of DLP technology allows for both decorative and practical applications.

The Future of DLP Printing Technology

The future of DLP printing holds exciting possibilities. As technology advances, we can expect even greater integration of smart features, enhanced material capabilities, and broader applications across various industries. Innovations in software will streamline the design process, making DLP technology more accessible to enthusiasts and professionals alike.

Frequently Asked Questions

1. What is the main advantage of DLP technology over other printing methods?

DLP technology offers superior speed and precision, allowing for faster printing of highly detailed objects compared to methods like FDM (Fused Deposition Modeling).

2. Can DLP printers use multiple types of resin?

Yes, many DLP printers are compatible with a variety of resins, including standard, flexible, and specialty materials, expanding their applications significantly.

3. What is the typical post-processing required for DLP prints?

Post-processing usually involves washing the printed object in isopropyl alcohol and curing it under UV light for added strength and durability.

4. Are DLP printers suitable for beginners?

While DLP printers can be more complex than some other types, many models come with user-friendly interfaces and guides, making them accessible for beginners.

5. How do I maintain my DLP printer?

Regular maintenance includes cleaning the resin vat, checking the light source, and ensuring the lens is clear to maintain optimal print quality.

Conclusion

Industrial Toy DLP technology is undeniably reshaping the printing landscape, offering unprecedented levels of detail, speed, and versatility. As we delve deeper into the advantages and applications of DLP printing, it becomes clear that this technology is not just a trend but a fundamental shift in how we create and produce. Whether for professional use or personal projects, embracing DLP technology can significantly elevate your printing experience, paving the way for creativity and innovation. As we look toward the future, the potential of DLP printing technology is boundless, promising even greater advancements and exciting opportunities for all users.

Keywords: Industrial Toy DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262