NEWS EVENTS

Mastering the Art of Detailed Printing with UV Resin 3D Printer: A Comprehensive Guide

2025-05-12

Mastering the Art of Detailed Printing with UV Resin 3D Printer

Table of Contents

- Introduction to UV Resin 3D Printing

- Benefits of UV Resin 3D Printing

- How UV Resin 3D Printers Work

- Essential Tools and Materials for UV Resin Printing

- Preparing Your UV Resin Printer for Detailed Printing

- Calibrating Your UV Resin Printer

- Techniques for Achieving High Detail in Prints

- Post-Processing Your Prints

- Frequently Asked Questions

- Conclusion

Introduction to UV Resin 3D Printing

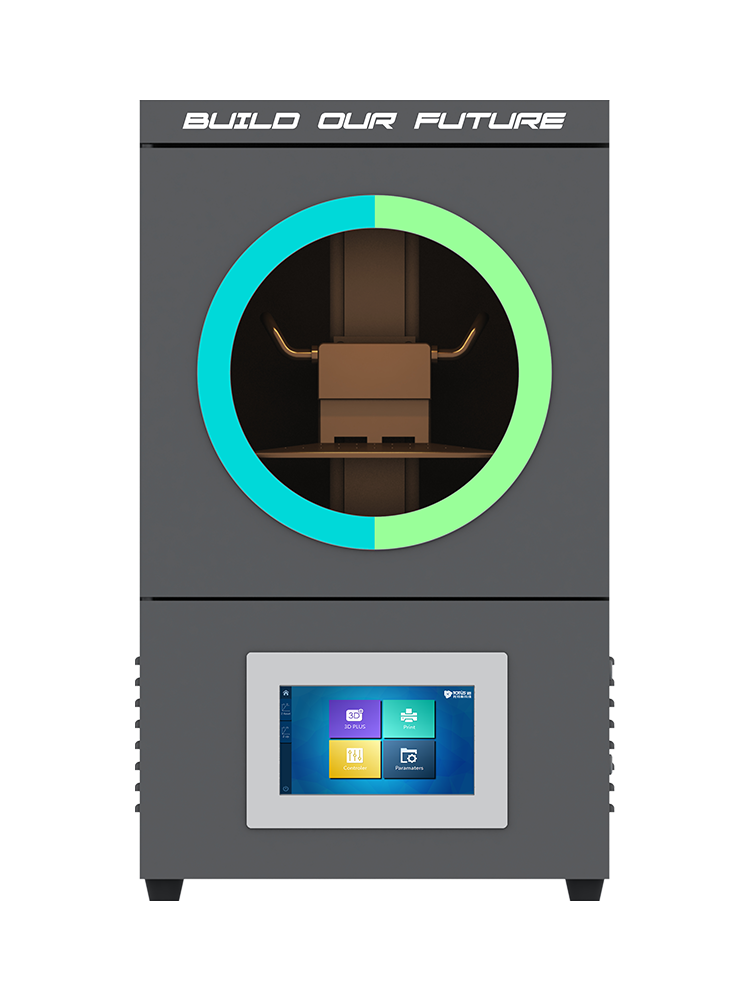

The emergence of **UV resin 3D printing** has transformed the landscape of additive manufacturing. This innovative technology allows creators to produce **highly detailed prints** with unmatched precision. By utilizing photopolymer resin that cures under UV light, users can achieve intricate designs that are often not possible with traditional filament printers.

Benefits of UV Resin 3D Printing

Understanding the advantages of UV resin printing is crucial for anyone looking to master this form of 3D printing.

Unmatched Detail and Resolution

One of the primary benefits is the ability to print at a **higher resolution**. UV resin printers can produce layers as thin as **25 microns**, allowing for incredible detail in even the most complex models.

Wide Range of Materials

UV resin printers offer versatility with a variety of resins available for different applications, including **flexible, rigid**, and **castable resins**. This variety allows users to select the perfect material for their specific project needs.

Fast Printing Speed

Compared to traditional 3D printing methods, UV resin printing can significantly reduce the time it takes to create detailed models, making it an efficient option for rapid prototyping and production.

How UV Resin 3D Printers Work

To effectively utilize a UV resin 3D printer, it is essential to understand its working mechanics.

The Printing Process

UV resin printers use a **light source**, typically an LED or LCD, to cure liquid resin layer by layer. The build platform descends into the resin tank, and as each layer is exposed to UV light, it solidifies. This process repeats until the print is complete.

Types of UV Resin Printers

There are primarily two types of UV resin printers: **SLA (Stereolithography)** and **DLP (Digital Light Processing)**. Each has its unique advantages and may be more suited for various applications based on speed and resolution requirements.

Essential Tools and Materials for UV Resin Printing

Before starting your UV resin printing journey, gathering the right tools and materials is crucial.

UV Resin

Choosing high-quality **photopolymer resins** tailored to your specific projects will ensure better results. Consider factors such as **color, viscosity**, and **cure speed**.

3D Printer and Accessories

Investing in a reliable UV resin printer and necessary accessories—such as **gloves, masks**, and **cleaning tools**—is essential for safety and optimal performance.

Post-Processing Equipment

Post-processing is a critical step in achieving the best results. Tools like **isopropyl alcohol**, **UV curing stations**, and **sandpaper** will help finish your prints beautifully.

Preparing Your UV Resin Printer for Detailed Printing

Setting up your printer correctly is vital for successful prints.

Printer Setup

Make sure to follow the manufacturer’s guidelines for **assembly**, ensuring that all components are correctly installed and calibrated.

Resin Tank Preparation

Properly prepare your resin tank by ensuring it is clean and free of impurities. A clean tank ensures better adhesion and reduces the risk of print failure.

Calibrating Your UV Resin Printer

Calibration is a crucial step in achieving high-quality prints.

Leveling the Build Platform

Ensure your build platform is perfectly leveled. This will reduce the risk of adhesion issues during the printing process.

Settings Adjustments

Adjust the settings on your printer for optimal results, including layer height, exposure time, and lift speed. Finding the right balance will enhance the detail in your prints.

Techniques for Achieving High Detail in Prints

To maximize the capabilities of your UV resin printer, consider these techniques:

Optimizing Model Designs

Design your models with **printability** in mind. Incorporate supports and ensure that there are no overhangs that could lead to print failures.

Utilizing Supports Effectively

Using supports is essential for maintaining the shape and detail of your prints. Ensure they are strategically placed to minimize cleanup after printing.

Experimenting with Layer Heights

Experiment with different layer heights to find the ideal setting for your specific resin and model. Thinner layers can enhance detail, while thicker layers can speed up the process.

Post-Processing Your Prints

Post-processing is where your prints truly come to life.

Cleaning Your Prints

After printing, gently clean your models using **isopropyl alcohol** to remove any uncured resin. This step is critical to achieving a professional finish.

Curing Your Prints

Utilize a UV curing station to fully cure your prints. This will enhance their strength and durability while ensuring an even finish.

Finishing Touches

Consider sanding, painting, or applying a clear coat for additional aesthetics. These final touches can elevate your prints significantly.

Frequently Asked Questions

1. What is UV resin printing?

UV resin printing is an additive manufacturing process that uses photopolymer resin cured by UV light to create detailed 3D models.

2. How does UV resin compare to FDM printing?

UV resin printing typically offers higher detail and smoother finishes compared to FDM (Fused Deposition Modeling) printing, which uses thermoplastic filaments.

3. Is UV resin safe to use?

While UV resin can be toxic before curing, it is safe to handle once fully cured. Always wear protective gear during printing.

4. How long does it take to print a model using a UV resin printer?

Print times vary based on model size and complexity, but UV resin printers are generally faster than FDM printers for detailed prints.

5. Can I use any resin in my UV printer?

No, it is essential to use resins specifically designed for your printer type (SLA or DLP) to ensure optimal results.

Conclusion

Mastering the art of detailed printing with a UV resin 3D printer opens up a world of creative possibilities. By understanding the technology, employing the right techniques, and investing in quality materials, we can achieve stunning results that showcase precision and artistry. Whether you are a hobbyist or a professional, embracing these practices will elevate your 3D printing projects to new heights. Embrace the journey of UV resin printing and let your creativity shine!

Keywords: uv resin lcd 3d printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262