NEWS EVENTS

Unlocking the Potential of Resin Wax DLP 3D Printers for Innovative Creations

2025-05-19

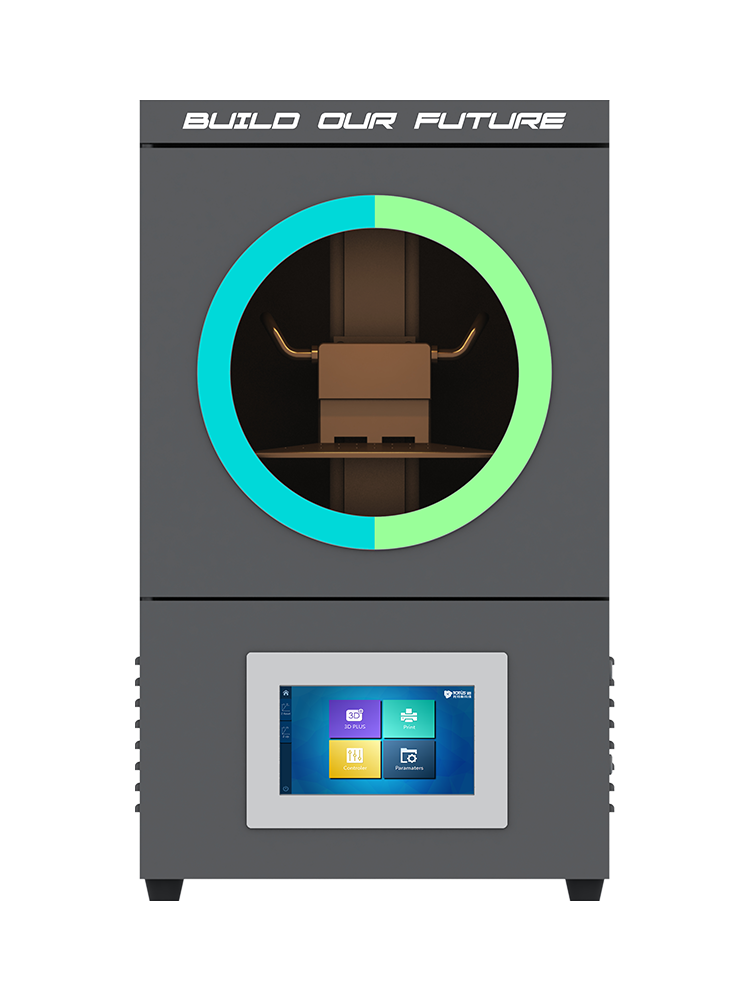

In recent years, the popularity of 3D printing technology has surged across various industries, particularly in the realm of consumer electronics. One notable advancement is the Resin Wax DLP (Digital Light Processing) 3D printer, which combines the precision of resin printing with the efficiency of light-based curing processes. This technology offers numerous advantages for professionals looking to craft intricate designs and prototypes.

Resin Wax DLP 3D printers utilize liquid resin, which hardens when exposed to specific light wavelengths, allowing for highly detailed and smooth finishes. This capability is particularly beneficial when creating complex geometries and fine details that traditional FDM (Fused Deposition Modeling) printers may struggle to reproduce accurately. The high resolution achievable with Resin Wax DLP technology makes it an ideal choice for producing detailed models, figurines, and intricate components used in various consumer electronic devices.

One of the standout features of Resin Wax DLP printers is their speed. The layer-by-layer printing process is significantly faster than many other 3D printing methods, making it possible to produce high-quality parts in a fraction of the time. This efficiency is particularly advantageous for rapid prototyping, where time-to-market is crucial. Designers and engineers can iterate their designs quickly, allowing for a more agile development process.

The materials used in Resin Wax DLP printing are specially formulated to provide excellent mechanical properties. These resins often exhibit superior strength, durability, and flexibility compared to standard thermoplastics. As a result, prototypes produced with this technology not only look impressive but also perform well under real-world conditions. Additionally, the ability to create parts with varying material properties within a single print opens up new avenues for innovation in product design.

However, it is important to note that the post-processing of printed parts is a critical step in achieving the best results. After the printing process, parts typically require cleaning and curing to reach their optimal strength and finish. This process can involve using isopropyl alcohol for cleaning and UV light for curing, ensuring that the final product meets the desired quality standards.

In conclusion, Resin Wax DLP 3D printers represent a significant evolution in 3D printing technology, particularly for the consumer electronics sector. Their ability to deliver high-resolution prints quickly and efficiently makes them a valuable tool for designers and engineers alike. As the demand for innovative products continues to grow, leveraging the capabilities of this technology can provide a competitive edge and pave the way for groundbreaking designs and applications.

Resin Wax DLP 3D printers utilize liquid resin, which hardens when exposed to specific light wavelengths, allowing for highly detailed and smooth finishes. This capability is particularly beneficial when creating complex geometries and fine details that traditional FDM (Fused Deposition Modeling) printers may struggle to reproduce accurately. The high resolution achievable with Resin Wax DLP technology makes it an ideal choice for producing detailed models, figurines, and intricate components used in various consumer electronic devices.

One of the standout features of Resin Wax DLP printers is their speed. The layer-by-layer printing process is significantly faster than many other 3D printing methods, making it possible to produce high-quality parts in a fraction of the time. This efficiency is particularly advantageous for rapid prototyping, where time-to-market is crucial. Designers and engineers can iterate their designs quickly, allowing for a more agile development process.

The materials used in Resin Wax DLP printing are specially formulated to provide excellent mechanical properties. These resins often exhibit superior strength, durability, and flexibility compared to standard thermoplastics. As a result, prototypes produced with this technology not only look impressive but also perform well under real-world conditions. Additionally, the ability to create parts with varying material properties within a single print opens up new avenues for innovation in product design.

However, it is important to note that the post-processing of printed parts is a critical step in achieving the best results. After the printing process, parts typically require cleaning and curing to reach their optimal strength and finish. This process can involve using isopropyl alcohol for cleaning and UV light for curing, ensuring that the final product meets the desired quality standards.

In conclusion, Resin Wax DLP 3D printers represent a significant evolution in 3D printing technology, particularly for the consumer electronics sector. Their ability to deliver high-resolution prints quickly and efficiently makes them a valuable tool for designers and engineers alike. As the demand for innovative products continues to grow, leveraging the capabilities of this technology can provide a competitive edge and pave the way for groundbreaking designs and applications.

Keywords: Resin Wax DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262