NEWS EVENTS

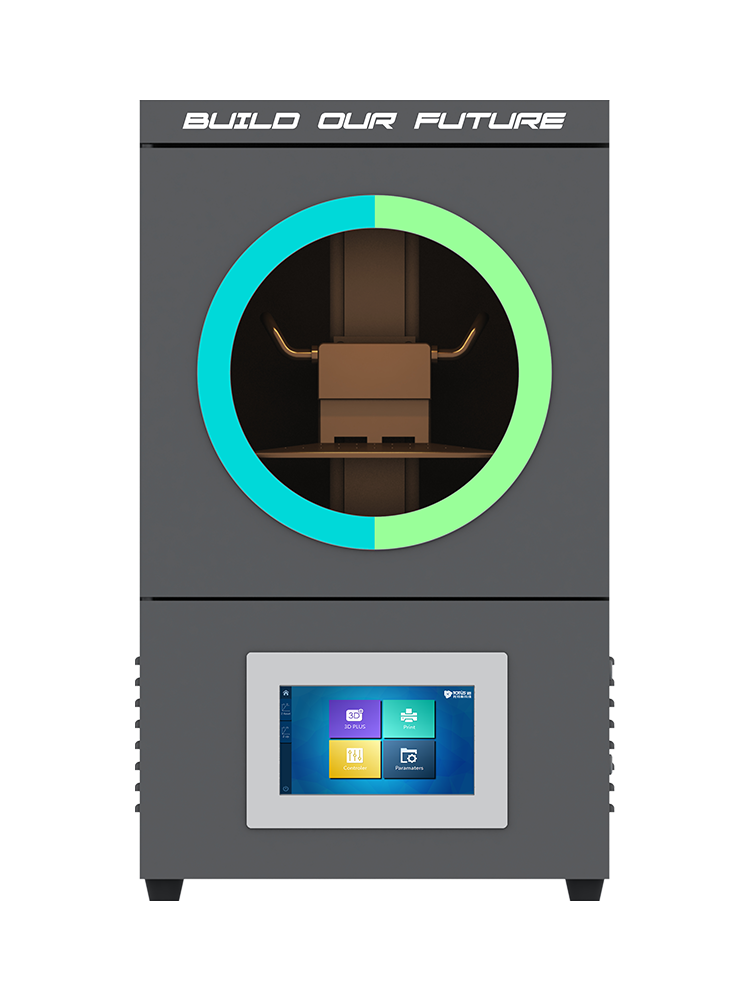

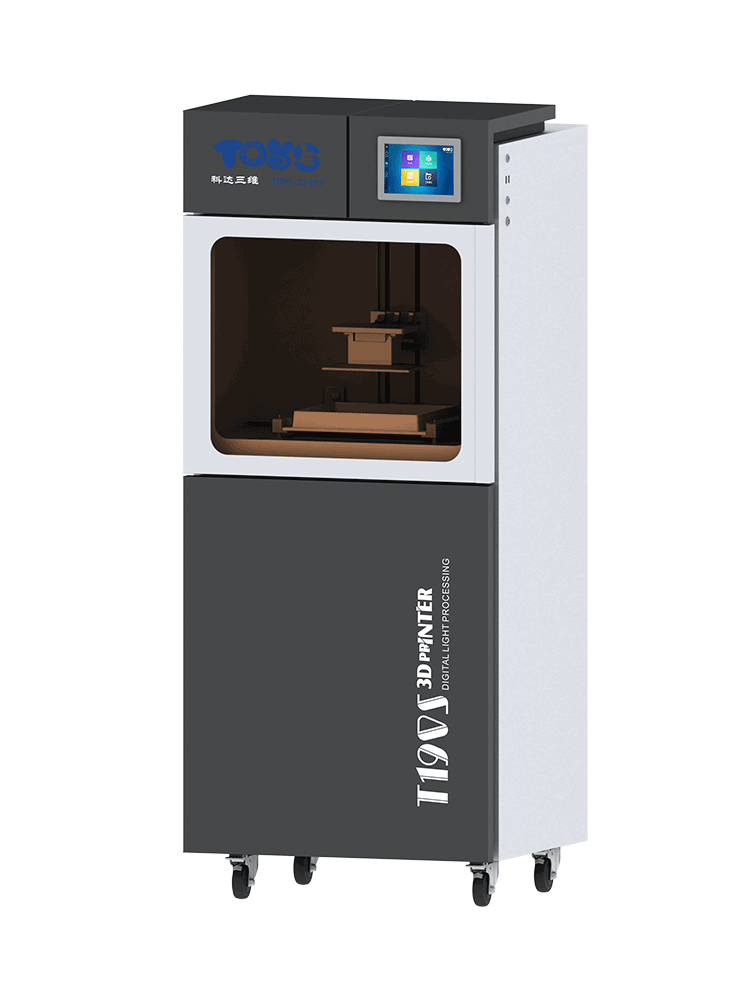

Elevating Your Printing Standards with Advanced Resin Wax DLP Technology

2025-06-23

Elevating Your Printing Standards with Advanced Resin Wax DLP Technology

Table of Contents

- 1. Introduction to Resin Wax DLP Technology

- 2. Understanding DLP Technology: A Game Changer in Printing

- 3. The Benefits of Resin Wax DLP Technology

- 3.1 High-Resolution Printing Capabilities

- 3.2 Faster Production Times

- 3.3 Cost-Effectiveness of Resin Wax DLP

- 4. Applications of Resin Wax DLP Technology

- 5. The Technology Behind DLP Printing

- 6. Considerations for Adopting Resin Wax DLP Technology

- 7. The Future of Resin Wax DLP Technology in Printing

- 8. FAQs About Resin Wax DLP Technology

- 9. Conclusion

1. Introduction to Resin Wax DLP Technology

In an age where precision and efficiency are paramount in the printing industry, **Resin Wax Digital Light Processing (DLP) technology** stands out as a breakthrough innovation. This technology enhances the quality, speed, and cost-effectiveness of printing, making it an invaluable asset for various applications. From intricate designs to large-scale production, DLP technology is reshaping the standards of what can be achieved in the printing domain.

2. Understanding DLP Technology: A Game Changer in Printing

**Digital Light Processing (DLP)** employs a digital micromirror device (DMD) that consists of thousands or millions of tiny mirrors, each representing a pixel. By projecting light onto a photosensitive resin, this technology creates high-resolution images layer by layer. This method contrasts with traditional printing techniques, which often struggle with detail and speed under high demand.

The integration of **resin wax** into DLP technology enhances its capabilities further, providing a smoother finish and improved durability. This combination opens the door to new possibilities in commercial and industrial printing, making it essential for businesses looking to innovate and elevate their output.

3. The Benefits of Resin Wax DLP Technology

3.1 High-Resolution Printing Capabilities

One of the primary advantages of resin wax DLP technology is its ability to produce **high-resolution prints** with stunning detail. This capability is crucial for industries such as jewelry, dental, and prototype manufacturing, where precision is non-negotiable. Unlike conventional printing methods, DLP technology delivers sharper images and finer details, resulting in products that stand out in terms of quality.

3.2 Faster Production Times

Time is of the essence in modern business. With resin wax DLP technology, production times are significantly reduced. The layer-by-layer approach allows for quicker build times, increasing efficiency and enabling businesses to meet tight deadlines without compromising quality. Organizations can ramp up their output, satisfying customer demands more effectively.

3.3 Cost-Effectiveness of Resin Wax DLP

Investing in resin wax DLP technology can lead to long-term cost savings. With reduced material waste and faster production cycles, businesses can lower their overhead costs. Additionally, the durability of the printed products means fewer replacements and repairs, further enhancing the cost-effectiveness of this advanced technology.

4. Applications of Resin Wax DLP Technology

4.1 Industrial Applications

In industrial settings, resin wax DLP technology is utilized for producing prototypes, tooling, and end-use parts. Its ability to handle complex geometries and deliver high precision makes it ideal for sectors such as aerospace, automotive, and manufacturing. Companies leverage this technology to enhance their production processes, reduce lead times, and improve overall product quality.

4.2 Consumer Products

The consumer goods sector has also witnessed a revolution thanks to resin wax DLP technology. From unique home décor items to customized gifts, the ability to produce intricate designs at scale has opened up new avenues for creativity and personalization. Businesses can offer consumers tailored products, enhancing their shopping experience.

4.3 Medical Industry Innovations

In the medical field, resin wax DLP technology is making remarkable advancements. It is employed in creating dental molds, surgical guides, and even prosthetics. The precision and detail achieved with this technology ensure that medical practitioners have reliable tools for enhancing patient outcomes, showcasing the critical role of innovation in healthcare.

5. The Technology Behind DLP Printing

5.1 How DLP Works

Understanding how resin wax DLP technology operates can shed light on its advantages. The process begins with a digital file, which the DLP printer slices into a series of thin layers. The DMD mirrors reflect light onto the resin, causing it to cure and solidify into the desired shape, layer by layer. This method is efficient and minimizes the likelihood of errors, ensuring a high-quality end product.

5.2 The Composition of Resin Wax

The resin wax used in DLP technology has been specially formulated to achieve optimal results. It combines photopolymers that react when exposed to specific wavelengths of light, creating a solid structure. The wax component enhances the finish, providing a smoother surface and improving the overall appearance of the printed object.

6. Considerations for Adopting Resin Wax DLP Technology

Before integrating resin wax DLP technology into your operations, several considerations must be addressed. These include the initial investment in machinery, training staff to operate the equipment, and understanding the specific needs of your business. Assessing these factors ensures a smooth transition and helps maximize the technology's benefits.

7. The Future of Resin Wax DLP Technology in Printing

As technology continues to evolve, the future of resin wax DLP technology looks promising. Innovations in materials and software are expected to enhance speed, precision, and versatility even further. Industries can anticipate more sustainable practices and smarter production methods, leading to a new era of printing standards.

8. FAQs About Resin Wax DLP Technology

8.1 What is the key advantage of using resin wax DLP technology?

The primary advantage is its ability to produce **high-resolution prints** with faster production times and lower costs, making it suitable for various industries.

8.2 How does resin wax differ from traditional printing methods?

Unlike traditional methods, resin wax DLP technology uses a light-based curing process, allowing for greater detail and less material waste.

8.3 Is resin wax DLP technology suitable for large-scale production?

Yes, it is ideal for large-scale production due to its speed and efficiency without sacrificing quality.

8.4 Can resin wax DLP technology be used in the medical field?

Absolutely, it is widely used for creating dental molds, surgical guides, and prosthetics.

8.5 What considerations should companies keep in mind when adopting this technology?

Companies should evaluate the initial investment, staff training, and their specific production needs to ensure successful implementation.

9. Conclusion

Resin wax DLP technology is not just a trend; it represents a significant advancement in the printing industry, offering **unmatched quality, speed, and cost-effectiveness**. By understanding its benefits and applications, businesses can elevate their standards and meet the growing demands of their customers. As we look to the future, embracing this technology will be crucial for anyone seeking to stay ahead in the competitive landscape of printing.

Keywords: Resin Wax DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262