NEWS EVENTS

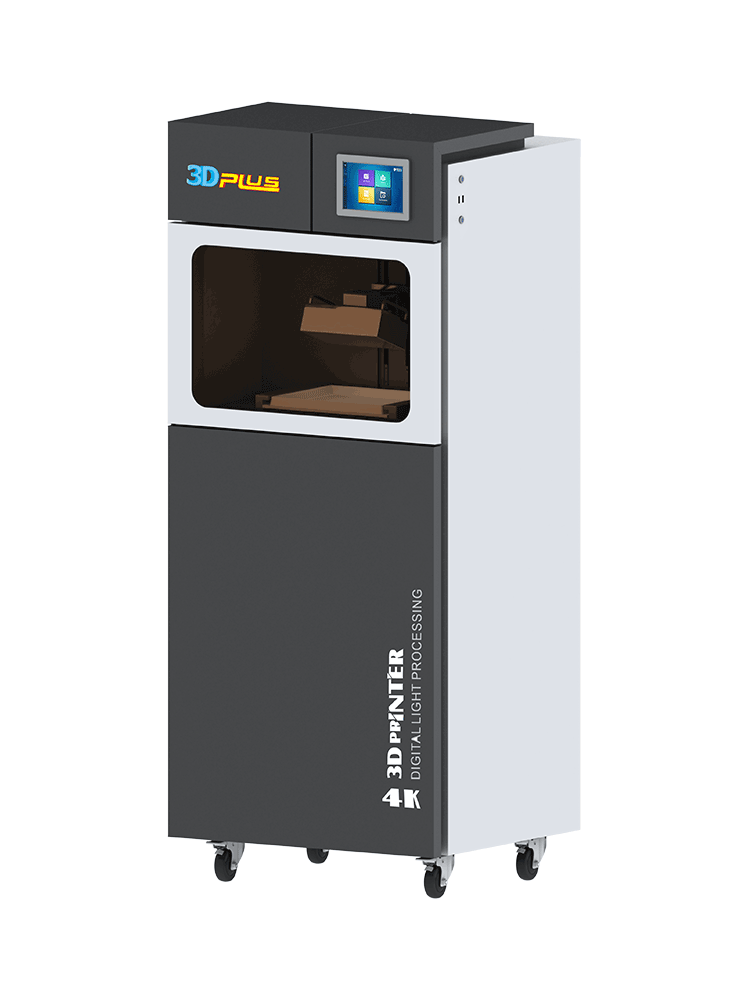

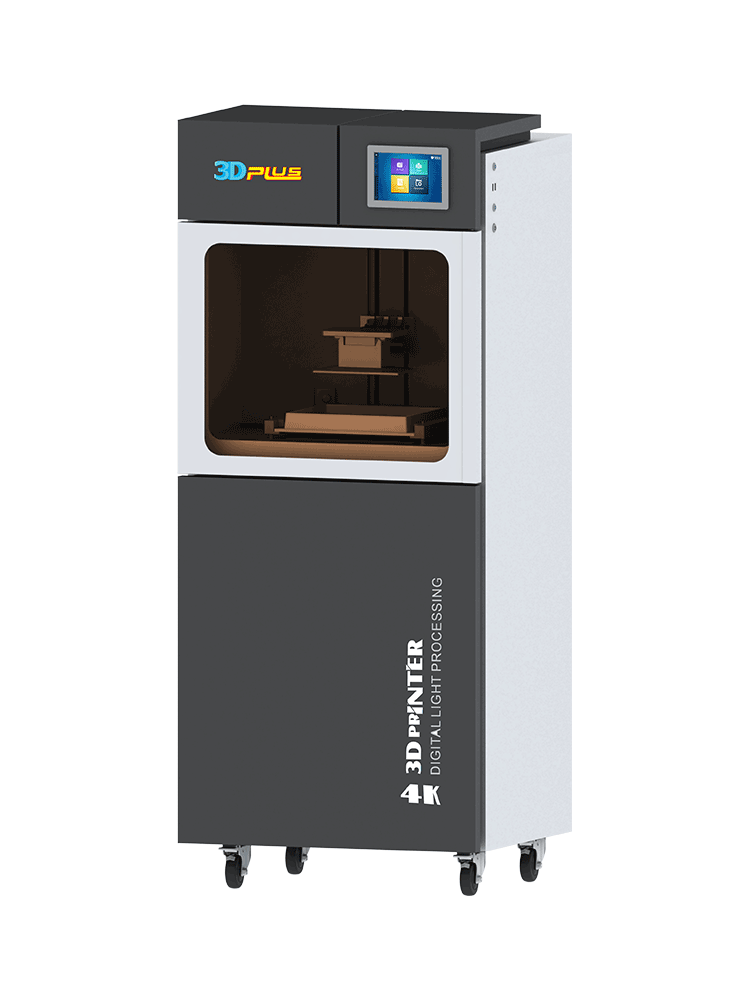

Unveiling the Power of Industrial Toy DLP 3D Printing in Consumer Electronics

2025-07-07

Unveiling the Power of Industrial Toy DLP 3D Printing in Consumer Electronics

Introduction to DLP 3D Printing Technology

DLP (Digital Light Processing) 3D printing is a groundbreaking technology that has revolutionized the manufacturing landscape in various industries, especially consumer electronics. Unlike traditional methods, DLP utilizes a digital light projector to cure liquid resin layer by layer, creating precise and intricate designs. This article dives into the specific advantages and applications of Industrial Toy DLP 3D printing within the consumer electronics realm.

The Evolution of 3D Printing in Consumer Electronics

The integration of 3D printing technologies in consumer electronics has evolved rapidly. Initially used for prototyping, 3D printing now plays a pivotal role in the entire product development lifecycle. As the technology has advanced, DLP 3D printing has emerged as a frontrunner, offering unparalleled speed, detail, and efficiency.

Advantages of DLP Technology in Electronics Manufacturing

DLP 3D printing presents numerous benefits that make it the ideal choice for manufacturing consumer electronics.

1. Speed and Efficiency

DLP technology is renowned for its speed. Unlike traditional methods that print layer by layer, DLP cures an entire layer at once, significantly reducing production time. This rapid prototyping capability allows designers and engineers to iterate quickly, bringing products to market faster.

2. High Precision and Detail

DLP 3D printing excels in producing highly detailed models with smooth surfaces and intricate features. This precision is particularly crucial in consumer electronics, where components must fit together perfectly to ensure functionality and aesthetic appeal.

3. Material Versatility

Industrial Toy DLP printers can work with a wide range of materials, including various resins tailored for specific applications. This versatility enables manufacturers to select materials that best suit their needs, whether for flexibility, durability, or aesthetic quality.

4. Cost-Effectiveness

Although the initial investment in DLP technology may be higher than traditional manufacturing methods, the long-term savings are substantial. Reduced material waste, lower labor costs, and the ability to produce low-volume runs without expensive molds make DLP an economically sound choice.

Applications of DLP 3D Printing in Consumer Electronics

The applications of DLP 3D printing within the consumer electronics sector are diverse and transformative.

1. Prototyping and Product Development

Designers use DLP printing for rapid prototyping, allowing them to visualize and test their ideas quickly. This capability leads to more innovative designs and faster feedback cycles, ultimately resulting in better products.

2. Customization and Personalization

DLP technology allows for high levels of customization, enabling brands to offer personalized products. Whether it’s a unique phone case or customized gaming accessories, DLP printing can meet consumer demands for individuality.

3. Complex Assembly Parts

Many consumer electronic devices consist of numerous small parts. DLP printing can produce complex components that fit together seamlessly, reducing assembly time and improving product reliability.

4. Sustainable Manufacturing Practices

With increasing awareness of environmental issues, DLP 3D printing supports sustainable practices by minimizing material waste and energy consumption. Manufacturers can produce only what they need, reducing excess inventory and waste.

Challenges Facing DLP 3D Printing in Consumer Electronics

While DLP 3D printing offers remarkable advantages, it also faces challenges that manufacturers must navigate.

1. Limited Build Volume

Many DLP printers have a limited build volume, which can restrict the size of the objects produced. However, manufacturers are continuously developing larger machines that can overcome this hurdle.

2. Material Costs

The cost of high-quality resins can be higher than traditional materials used in manufacturing consumer electronics. As demand increases and production scales up, prices are expected to decrease.

3. Post-Processing Requirements

Objects created using DLP printing often require post-processing, such as cleaning and curing, which can add time to the production process. However, advancements in automation are helping to minimize these additional steps.

Future Trends in DLP 3D Printing for Consumer Electronics

The future of DLP 3D printing in consumer electronics looks promising, with several trends on the horizon.

1. Advanced Materials Development

Ongoing research in materials science will lead to the creation of new resins that offer enhanced properties, such as improved strength, flexibility, and thermal resistance.

2. Integration with AI and Automation

The integration of AI technologies in DLP printers will enable smarter printing processes, optimizing parameters in real-time for better outcomes. Automation will also streamline workflows, enhancing efficiency even further.

3. Expanding Applications

As industries continue to explore 3D printing, we can expect to see even more innovative applications emerge, from consumer electronics to complex machinery and beyond.

FAQs About Industrial Toy DLP 3D Printing in Consumer Electronics

1. What is DLP 3D printing?

DLP 3D printing is a technology that uses a digital light projector to cure liquid resin layer by layer, allowing for high-speed and precise printing.

2. How does DLP compare to other 3D printing technologies?

DLP printing is generally faster and offers higher resolution compared to FDM (Fused Deposition Modeling) and SLA (Stereolithography) due to its layer-wise curing process.

3. What types of materials can be used in DLP printing?

DLP printers can use a variety of resins, including flexible, rigid, and even biocompatible materials, catering to different product requirements.

4. Is DLP 3D printing cost-effective for small production runs?

Yes, DLP printing is particularly cost-effective for low-volume production as it eliminates the need for expensive molds and tooling.

5. What are the environmental benefits of DLP 3D printing?

DLP 3D printing minimizes material waste, reduces energy consumption, and allows for on-demand production, contributing to more sustainable manufacturing practices.

Conclusion

The advent of Industrial Toy DLP 3D printing is transforming the consumer electronics industry, offering speed, precision, and versatility. As manufacturers continue to explore and adopt this innovative technology, we can anticipate a future filled with customized, efficient, and sustainable products. The challenges currently facing DLP printing may be significant, but ongoing advancements in materials and automation promise a bright horizon, ensuring that DLP remains a critical tool in the evolution of consumer electronics.

Keywords: Industrial Toy DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262