NEWS EVENTS

Empowering Artisans: Using DLP 3D Printers to Elevate Jewelry Designs

2025-08-18

Empowering Artisans: Using DLP 3D Printers to Elevate Jewelry Designs

Table of Contents

1. Introduction to DLP 3D Printing in Jewelry

2. What is DLP 3D Printing?

3. Benefits of DLP Printers for Jewelry Design

- Precision and Detail in Designs

- Material Flexibility and Variety

4. The Jewelry Design Process with DLP 3D Printing

- Conceptualization and Planning

- Design Software Options for Artisans

- Prototyping and Production

5. Real-World Applications of DLP 3D Printing in Jewelry

6. Tips for Artisans to Maximize DLP Technology

- Keeping Up with Trends

- Networking and Community Engagement

7. The Future of DLP 3D Printing in Jewelry Design

8. FAQs

9. Conclusion

Introduction to DLP 3D Printing in Jewelry

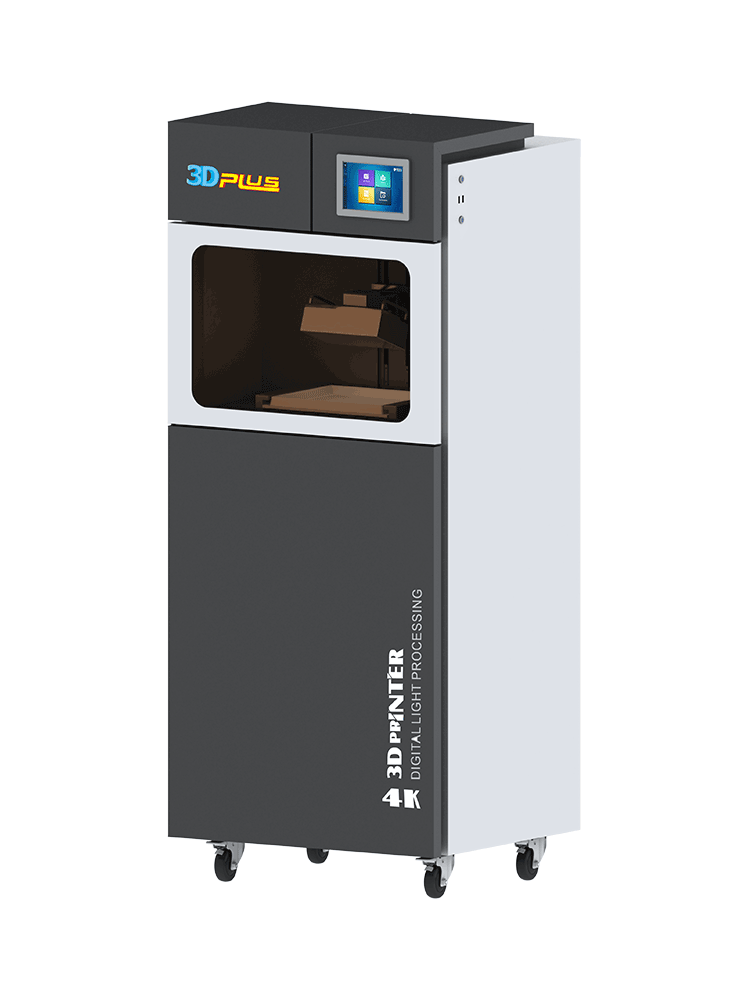

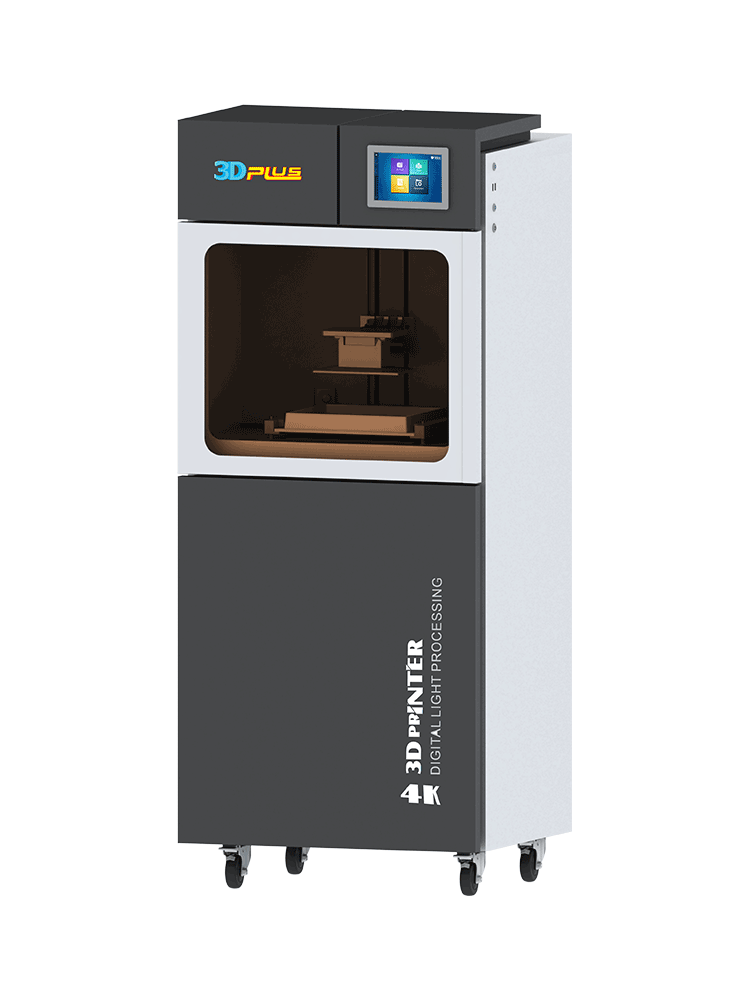

In recent years, **Digital Light Processing (DLP) 3D printing** has emerged as a groundbreaking technology, reshaping the landscape of jewelry design. This innovative method allows artisans to create intricate and highly detailed jewelry pieces that were once challenging to manufacture using traditional techniques. As the demand for unique, customizable jewelry grows, DLP printers are empowering artisans by providing them with tools to enhance their creative expression. This article explores the various facets of using DLP 3D printers to elevate jewelry designs, from the benefits to the design process and future prospects.

What is DLP 3D Printing?

DLP 3D printing is a type of additive manufacturing that uses a digital light projector to cure resin, layer by layer, into solid objects. Unlike traditional 3D printing methods like FDM (Fused Deposition Modeling), where materials are extruded through a nozzle, DLP projects light onto a vat of liquid resin, curing it almost instantaneously. This results in faster print times and higher resolution, making DLP an ideal choice for detailed applications such as jewelry making.

Benefits of DLP Printers for Jewelry Design

Utilizing DLP 3D printers brings numerous advantages to artisans looking to enhance their jewelry creations.

Precision and Detail in Designs

One of the hallmark features of DLP technology is its ability to produce exceptionally fine details. Artisans can achieve intricate designs with precise geometries that would be difficult, if not impossible, to replicate using traditional methods. This level of precision allows for unique customization options, enabling jewelers to cater to specific tastes and preferences.

Material Flexibility and Variety

DLP printers are compatible with a wide range of resins, including those specifically formulated for jewelry. These materials can mimic the properties of metals, plastics, and ceramics, providing artisans with the flexibility to experiment with different textures and finishes. Whether crafting delicate rings or bold statement pieces, the material versatility offered by DLP printing can significantly enhance the creative process.

The Jewelry Design Process with DLP 3D Printing

Creating jewelry with DLP 3D printing involves several key steps that integrate technology with artistry.

Conceptualization and Planning

Every jewelry piece begins with an idea. Artisans should spend time brainstorming and sketching their designs before moving to the digital phase. Conceptualization helps in establishing the aesthetic and functional elements that will guide the subsequent steps of the design process.

Design Software Options for Artisans

To bring their ideas to life, artisans need to utilize CAD (Computer-Aided Design) software. Popular software options for jewelry design include Rhino, Tinkercad, and Blender, each offering unique tools that facilitate the modeling of complex shapes and structures. Choosing the right software is crucial for achieving the desired level of detail and creativity.

Prototyping and Production

Once the design is finalized, artisans can create a prototype using a DLP 3D printer. The prototyping phase allows for adjustments and refinements, ensuring that the final product aligns with the original vision. Following prototyping, artisans can proceed to production, scaling up their designs for larger orders or individual clients.

Real-World Applications of DLP 3D Printing in Jewelry

DLP 3D printing is being widely adopted by many artisans and companies within the jewelry industry. Applications include creating intricate designs for rings, pendants, earrings, and custom pieces tailored to customer specifications. Notably, brands are leveraging DLP printing to create limited-edition collections, appealing to collectors and enthusiasts alike.

Tips for Artisans to Maximize DLP Technology

Incorporating DLP 3D printing into jewelry design presents exciting opportunities, but artisans should consider several tips to maximize their use of this technology.

Keeping Up with Trends

The jewelry market is dynamic, with trends evolving constantly. Artisans should remain informed about the latest design trends, materials, and technologies. Engaging in community forums, attending trade shows, and following industry leaders on social media can provide valuable insights.

Networking and Community Engagement

Building connections with fellow artisans and professionals can foster collaboration and innovation. Joining local or online jewelry-making groups can expose artisans to new techniques and ideas. Community engagement can also lead to potential partnerships and collaborations that enhance brand visibility.

The Future of DLP 3D Printing in Jewelry Design

As technology continues to advance, the future of DLP 3D printing in jewelry design looks promising. Innovations in materials, software, and printing techniques are expected to enhance the capabilities of DLP printers, further empowering artisans. The growing popularity of sustainable practices may also influence the development of eco-friendly resins, allowing artisans to create beautiful pieces with minimal environmental impact.

FAQs

1. What is the cost of a DLP 3D printer?

The cost of DLP 3D printers can vary significantly based on factors such as brand, features, and specifications. Entry-level models can start around $200, while industrial-grade printers may exceed $5,000.

2. How long does it take to print a jewelry piece using DLP technology?

Printing times can vary based on the complexity and size of the design. However, DLP technology typically allows for faster printing compared to other methods, with some smaller pieces taking only a few hours to complete.

3. Can I use DLP 3D printing for mass production?

Yes, DLP 3D printing can be used for small to medium-scale production runs. Artisans can create multiple copies of a design efficiently, making it suitable for limited-edition collections and custom orders.

4. What types of materials are suitable for DLP jewelry printing?

DLP printing is compatible with various resins, including castable resins designed for jewelry. These materials can replicate the look and feel of metals and other materials, enabling diverse design possibilities.

5. Is post-processing required after 3D printing?

Yes, most DLP-printed jewelry pieces require post-processing steps such as washing to remove excess resin, curing under UV light, and finishing techniques like polishing to achieve the desired look and feel.

Conclusion

DLP 3D printing is revolutionizing the jewelry design industry by empowering artisans with unmatched precision, detail, and material versatility. As the technology continues to evolve, it opens new avenues for creativity and innovation, allowing jewelers to create unique, customized pieces that resonate with their clients. By understanding the design process, keeping up with trends, and engaging with the community, artisans can harness the full potential of DLP 3D printing to elevate their craft and thrive in a competitive market. Embracing this technology not only enhances their artistry but also positions them at the forefront of the evolving jewelry landscape.

Keywords: Jewelry DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262