NEWS EVENTS

Unlocking Creativity: The Benefits of Jewelry DLP 3D Printers for Artisans

2025-09-22

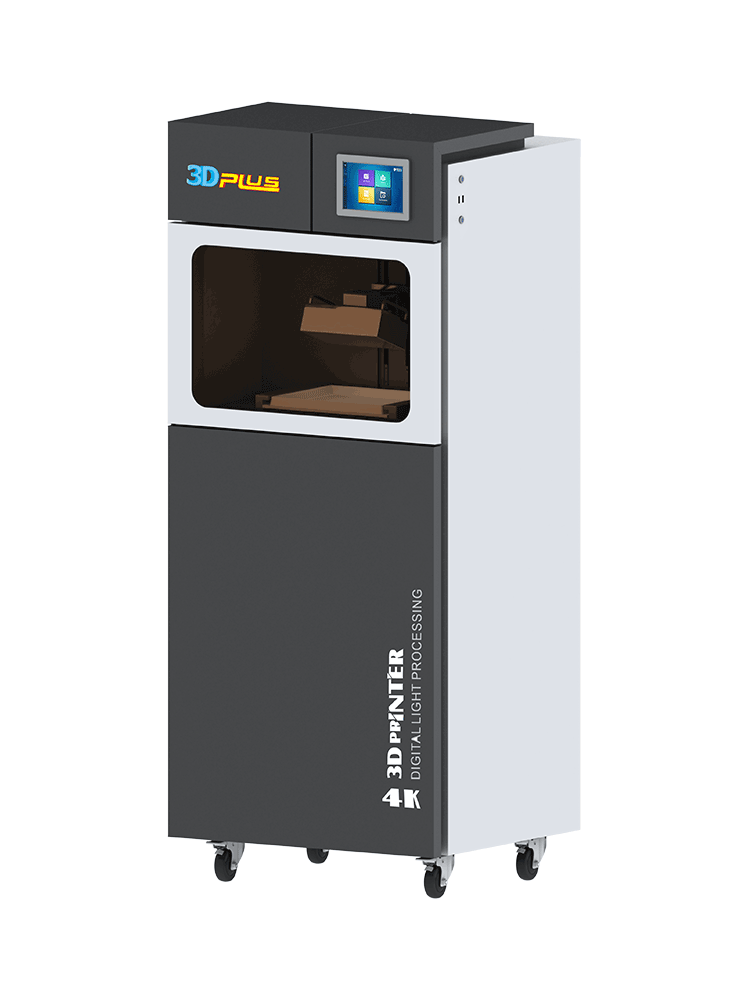

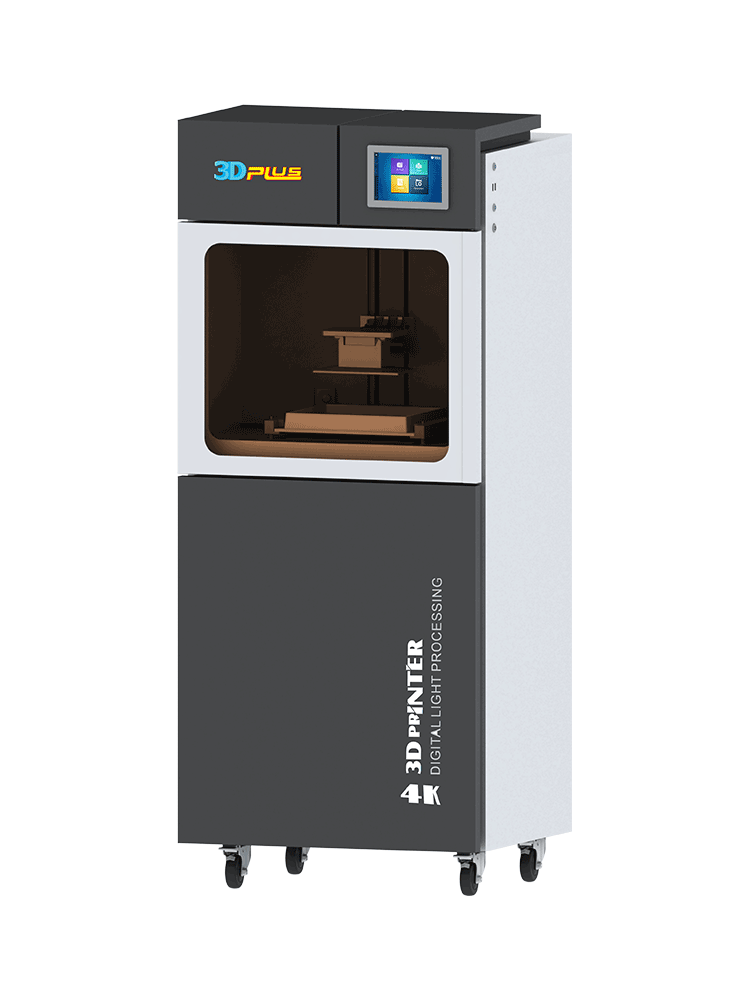

In the realm of modern jewelry design, Jewelry DLP 3D Printers have emerged as groundbreaking tools that not only streamline the manufacturing process but also empower artisans to push the boundaries of their creativity. DLP, or Digital Light Processing, is a technology that utilizes a digital light projector to cure photosensitive resin layer by layer, allowing for precise and detailed printing. This method is particularly advantageous in jewelry making, where intricate details and high precision are paramount.

One of the primary benefits of using a Jewelry DLP 3D Printer is the ability to create complex designs that would be extremely challenging, if not impossible, to achieve using traditional methods. Artisans can experiment with innovative shapes, intricate patterns, and unique textures, resulting in one-of-a-kind pieces that stand out in a competitive market. This technology enables designers to bring their visions to life quickly, significantly reducing the time from conception to production.

Moreover, Jewelry DLP 3D Printers are highly efficient. Traditional jewelry manufacturing often involves lengthy processes that require multiple steps, including carving, molding, and casting. With DLP printing, the entire process can be significantly condensed. A model can be designed digitally and printed in a matter of hours, allowing jewelers to meet tight deadlines and respond to market demands more effectively. This speed not only increases productivity but also offers the flexibility to create smaller batches or even custom pieces, catering to individual client needs.

Another noteworthy advantage of Jewelry DLP 3D Printers is their cost-effectiveness. While the initial investment in a 3D printer may seem substantial, the long-term savings are considerable. The reduction in material waste, combined with the ability to produce items on-demand, can lead to lower production costs. Furthermore, the automation of the printing process minimizes labor costs associated with traditional craftsmanship.

In addition to practical benefits, Jewelry DLP 3D Printers also foster sustainability in the jewelry industry. As artisans can produce items more efficiently and with less waste, the environmental impact of jewelry manufacturing is lessened. Many printers also use biodegradable resins or recyclable materials, contributing to a more eco-friendly approach to design.

As the technology continues to evolve, the potential for Jewelry DLP 3D Printers in the world of jewelry design will only expand. Artisans who embrace this innovative approach will find themselves at the forefront of a new era in jewelry making, characterized by creativity, efficiency, and sustainability. Whether you are a seasoned jeweler or a budding designer, investing in a Jewelry DLP 3D Printer could unlock new possibilities for your artistry and business.

One of the primary benefits of using a Jewelry DLP 3D Printer is the ability to create complex designs that would be extremely challenging, if not impossible, to achieve using traditional methods. Artisans can experiment with innovative shapes, intricate patterns, and unique textures, resulting in one-of-a-kind pieces that stand out in a competitive market. This technology enables designers to bring their visions to life quickly, significantly reducing the time from conception to production.

Moreover, Jewelry DLP 3D Printers are highly efficient. Traditional jewelry manufacturing often involves lengthy processes that require multiple steps, including carving, molding, and casting. With DLP printing, the entire process can be significantly condensed. A model can be designed digitally and printed in a matter of hours, allowing jewelers to meet tight deadlines and respond to market demands more effectively. This speed not only increases productivity but also offers the flexibility to create smaller batches or even custom pieces, catering to individual client needs.

Another noteworthy advantage of Jewelry DLP 3D Printers is their cost-effectiveness. While the initial investment in a 3D printer may seem substantial, the long-term savings are considerable. The reduction in material waste, combined with the ability to produce items on-demand, can lead to lower production costs. Furthermore, the automation of the printing process minimizes labor costs associated with traditional craftsmanship.

In addition to practical benefits, Jewelry DLP 3D Printers also foster sustainability in the jewelry industry. As artisans can produce items more efficiently and with less waste, the environmental impact of jewelry manufacturing is lessened. Many printers also use biodegradable resins or recyclable materials, contributing to a more eco-friendly approach to design.

As the technology continues to evolve, the potential for Jewelry DLP 3D Printers in the world of jewelry design will only expand. Artisans who embrace this innovative approach will find themselves at the forefront of a new era in jewelry making, characterized by creativity, efficiency, and sustainability. Whether you are a seasoned jeweler or a budding designer, investing in a Jewelry DLP 3D Printer could unlock new possibilities for your artistry and business.

Keywords: Jewelry DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262