NEWS EVENTS

Unveiling the Future: UV Resin LCD 3D Printers in Consumer Electronics

2025-09-29

Unveiling the Future: UV Resin LCD 3D Printers in Consumer Electronics

Table of Contents

1. Introduction to UV Resin LCD 3D Printing

2. How UV Resin LCD 3D Printers Work

3. Key Benefits of UV Resin LCD 3D Printers

4. Applications of UV Resin LCD 3D Printers

4.1 Prototyping and Product Development

4.2 Art and Design

4.3 Medical Applications

5. Comparing UV Resin LCD 3D Printers to Other 3D Printing Technologies

6. Future Trends in UV Resin LCD 3D Printing

7. Choosing the Right UV Resin LCD 3D Printer for Your Needs

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to UV Resin LCD 3D Printing

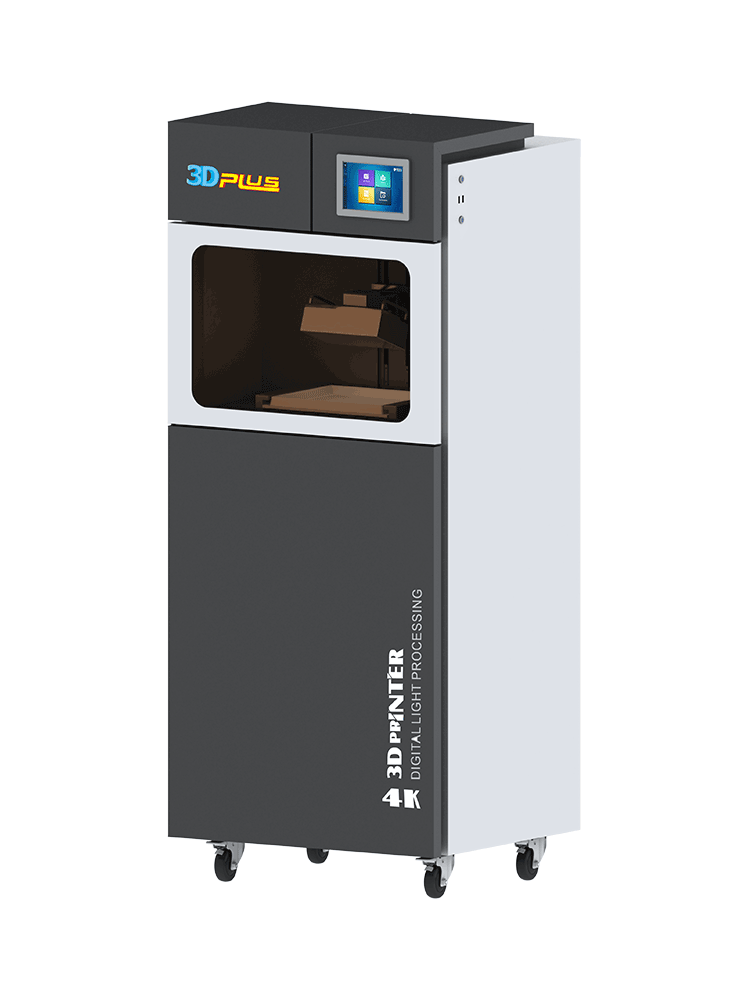

As we navigate the digital age, **3D printing technology** continues to revolutionize various industries, including consumer electronics. Among the most exciting innovations is the **UV Resin LCD 3D printer**, a device that offers unparalleled precision and versatility. This article explores the workings, advantages, applications, and future of UV resin LCD 3D printers, unveiling how they are shaping the consumer electronics landscape.

2. How UV Resin LCD 3D Printers Work

UV resin LCD 3D printers utilize a process known as **stereolithography** (SLA), where a light source cures liquid resin layer by layer to create a solid object. Here’s a step-by-step breakdown of how these printers operate:

2.1 The Printing Process

1. **Design Creation**: Users create a 3D model using computer-aided design (CAD) software. This model is sliced into thin horizontal layers.

2. **Resin Preparation**: The printer fills its vat with UV-sensitive resin. This liquid is a crucial component that hardens when exposed to ultraviolet light.

3. **Layer Curing**: A UV light source, typically an LCD panel, exposes the resin to light, curing it layer by layer. Each cured layer bonds to the one below, gradually building the final object.

4. **Post-Processing**: After printing, supports are removed, and the object may require further curing under UV light to achieve optimal strength and finish.

2.2 Advantages of LCD Technology

LCD technology allows for high-resolution printing with greater speed and efficiency. The use of monochrome LCD screens enhances the exposure time, allowing for faster layer curing and reducing print times significantly.

3. Key Benefits of UV Resin LCD 3D Printers

UV resin LCD 3D printers offer numerous advantages that make them a preferred choice for many users:

3.1 Exceptional Detail and Precision

These printers can achieve extremely fine details, with layer resolutions often as small as 25 microns. This capability is ideal for intricate designs, such as jewelry or figurines.

3.2 Versatility in Material Selection

UV resin printers can work with a variety of resin types, including flexible, rigid, and transparent materials. This range allows users to experiment with different properties, tailoring prints to specific needs.

3.3 Faster Print Speeds

With advancements in technology, the speed at which UV resin LCD printers operate has dramatically improved, making them suitable for both rapid prototyping and mass production.

3.4 Environmentally Friendly Options

Some manufacturers now offer UV resins that are less toxic and more environmentally friendly, appealing to eco-conscious consumers.

4. Applications of UV Resin LCD 3D Printers

The applications of UV resin LCD 3D printers are vast and varied, spanning multiple industries.

4.1 Prototyping and Product Development

In the consumer electronics sector, rapid prototyping is crucial. UV resin 3D printing allows designers to create functional prototypes that can be tested and modified quickly. This iterative process accelerates product development cycles.

4.2 Art and Design

Artists and designers leverage the capabilities of UV resin printing to produce intricate sculptures, custom designs, and artistic models that were previously difficult or impossible to achieve with traditional methods.

4.3 Medical Applications

In the medical field, UV resin LCD 3D printers are used to create custom implants, dental models, and surgical guides, enhancing precision in patient care and treatment planning.

5. Comparing UV Resin LCD 3D Printers to Other 3D Printing Technologies

The 3D printing landscape is diverse, with various technologies available. Below, we compare UV resin LCD 3D printers to other prevalent methods:

5.1 Fused Deposition Modeling (FDM)

FDM printers extrude melted plastic filament to build objects layer by layer. While FDM is often more affordable and easier to use, UV resin printers provide superior detail and finish quality.

5.2 Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material, creating strong parts without the need for support structures. However, SLS printers are typically more expensive than UV resin printers and may require more post-processing.

5.3 Digital Light Processing (DLP)

DLP technology is similar to LCD but uses a projector to cure resin. DLP printers can achieve high speeds but may not offer the same level of detail as LCD printers.

6. Future Trends in UV Resin LCD 3D Printing

The future of UV resin LCD 3D printing looks promising as technology continues to evolve. Some key trends include:

6.1 Enhanced Material Properties

As research continues, we expect to see advancements in resin formulations that offer improved mechanical properties, such as increased flexibility, strength, and heat resistance.

6.2 Increased Automation

Future UV resin printers may incorporate more automated features for post-processing, such as built-in washing and curing stations, enhancing user convenience.

6.3 Expanded Applications Across Industries

With innovations in 3D printing, we anticipate greater adoption of UV resin technology in various fields, including aerospace, automotive, and even fashion.

7. Choosing the Right UV Resin LCD 3D Printer for Your Needs

Selecting the perfect UV resin LCD printer involves considering several factors:

7.1 Budget Considerations

Evaluate the total cost of ownership, including initial purchase price, ongoing resin costs, and maintenance.

7.2 Print Volume and Size

Consider the maximum build volume and whether it meets your project requirements. Larger build sizes may be necessary for specific applications.

7.3 Resolution and Speed

Look for printers that offer adjustable resolutions to suit various projects and evaluate print speeds to ensure efficiency.

7.4 Community and Support

Join user communities or forums to gain insights into specific models, troubleshooting tips, and access to customer support.

8. Frequently Asked Questions (FAQs)

8.1 What is UV resin used for in 3D printing?

UV resin is used as the material that solidifies under UV light, allowing for the creation of detailed and durable 3D prints.

8.2 How long does it take to print an object using a UV resin LCD printer?

Print times vary depending on the object's size and complexity, but many prints can be completed within a few hours.

8.3 Are UV resin printers safe to use at home?

While UV resin can be toxic, proper handling, use of gloves, and ventilation can minimize risks. It’s important to follow safety guidelines.

8.4 Can I use any resin in a UV resin LCD printer?

It’s essential to use resins specifically designed for your printer to ensure compatibility and optimal results.

8.5 What maintenance is required for UV resin printers?

Regular maintenance includes cleaning the resin vat, checking the LCD screen for damage, and occasionally replacing worn parts.

9. Conclusion

UV resin LCD 3D printers are at the forefront of innovation in consumer electronics, offering unmatched precision, speed, and versatility. As we continue to explore their capabilities, it’s clear that these devices will play a pivotal role in the future of manufacturing, design, and beyond. By understanding their workings and keeping abreast of emerging trends, individuals and businesses alike can harness the full potential of 3D printing technology, paving the way for exciting new possibilities in the digital age.

Keywords: uv resin lcd 3d printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262