NEWS EVENTS

Exploring the Benefits and Applications of Resin Wax DLP 3D Printers

2025-10-06

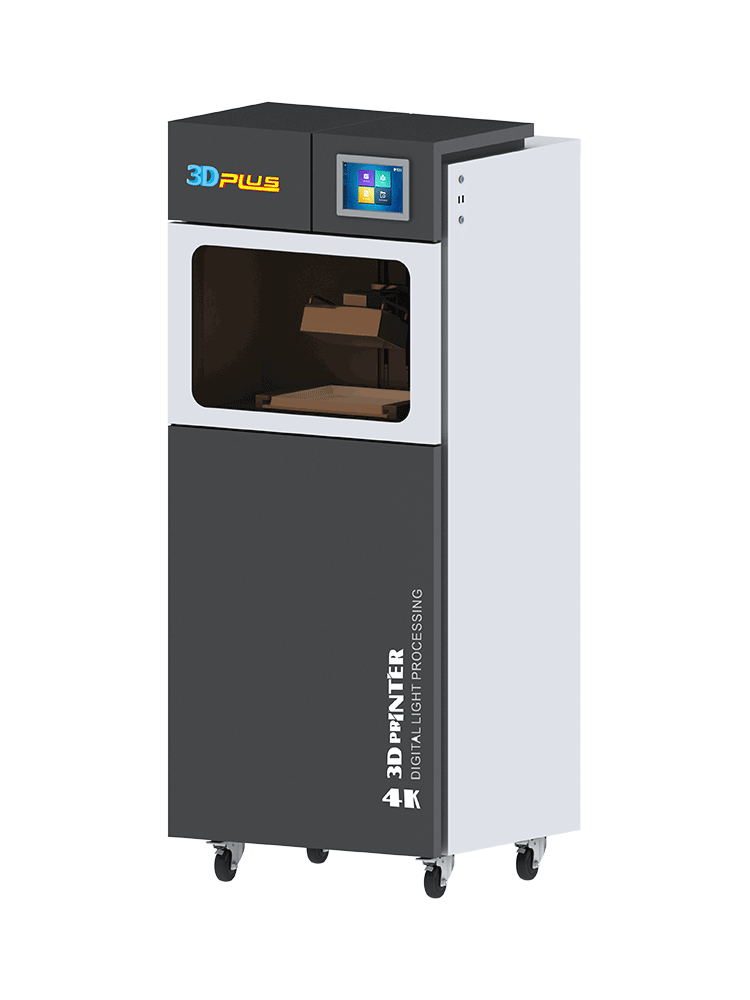

Resin Wax DLP (Digital Light Processing) 3D printers represent a breakthrough in additive manufacturing, offering precision and detail that is essential for various applications. This technology utilizes liquid resin that hardens when exposed to specific wavelengths of light, allowing for the creation of intricate designs and structures. One of the remarkable features of resin wax DLP printing is its ability to produce highly detailed parts with smooth surfaces, making it ideal for industries that demand meticulous craftsmanship.

One of the primary advantages of resin wax DLP 3D printers is their speed. Unlike traditional printing techniques that might take hours to produce a single item, DLP technology can significantly reduce production times. The process works by projecting an entire layer of the design at once, rather than tracing it line by line, which contributes to faster build times. This efficiency is particularly beneficial for businesses looking to streamline their operations and reduce lead times in production.

Another important aspect of resin wax DLP 3D printers is the variety of materials they can utilize. The resin used in these printers can be formulated to exhibit different properties, such as increased durability, flexibility, or even biocompatibility for certain medical applications. This versatility opens up a myriad of possibilities across various industries, including jewelry design, dental models, and even prototyping for consumer electronics.

Moreover, the resolution of the prints produced by resin wax DLP printers is often superior to those made with filament-based 3D printers. The layer thickness can be as fine as 25 microns, resulting in parts that display intricate details and smooth finishes. This level of precision is particularly advantageous for industries where aesthetics and accuracy are paramount, such as in the production of custom jewelry or high-quality dental implants.

As the world increasingly embraces digital fabrication, the role of resin wax DLP 3D printers continues to expand. These printers have become essential tools in the toolkit of designers, engineers, and artists, enabling them to bring their visions to life with remarkable fidelity. As technology advances, we can anticipate even more innovative applications and improved materials, further enhancing the capabilities of resin wax DLP 3D printing.

In summary, the evolution of resin wax DLP 3D printers marks a significant milestone in the realm of additive manufacturing. Their speed, versatility, and high-resolution output make them a valuable asset in numerous industries, from consumer electronics to healthcare. Understanding the benefits and potential applications of this technology can empower businesses and individuals to harness the full potential of 3D printing in their creative and production endeavors.

One of the primary advantages of resin wax DLP 3D printers is their speed. Unlike traditional printing techniques that might take hours to produce a single item, DLP technology can significantly reduce production times. The process works by projecting an entire layer of the design at once, rather than tracing it line by line, which contributes to faster build times. This efficiency is particularly beneficial for businesses looking to streamline their operations and reduce lead times in production.

Another important aspect of resin wax DLP 3D printers is the variety of materials they can utilize. The resin used in these printers can be formulated to exhibit different properties, such as increased durability, flexibility, or even biocompatibility for certain medical applications. This versatility opens up a myriad of possibilities across various industries, including jewelry design, dental models, and even prototyping for consumer electronics.

Moreover, the resolution of the prints produced by resin wax DLP printers is often superior to those made with filament-based 3D printers. The layer thickness can be as fine as 25 microns, resulting in parts that display intricate details and smooth finishes. This level of precision is particularly advantageous for industries where aesthetics and accuracy are paramount, such as in the production of custom jewelry or high-quality dental implants.

As the world increasingly embraces digital fabrication, the role of resin wax DLP 3D printers continues to expand. These printers have become essential tools in the toolkit of designers, engineers, and artists, enabling them to bring their visions to life with remarkable fidelity. As technology advances, we can anticipate even more innovative applications and improved materials, further enhancing the capabilities of resin wax DLP 3D printing.

In summary, the evolution of resin wax DLP 3D printers marks a significant milestone in the realm of additive manufacturing. Their speed, versatility, and high-resolution output make them a valuable asset in numerous industries, from consumer electronics to healthcare. Understanding the benefits and potential applications of this technology can empower businesses and individuals to harness the full potential of 3D printing in their creative and production endeavors.

Keywords: Resin Wax DLP 3D Printer

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262