NEWS EVENTS

Micro-nano 3D Printing Sets the Stage for the Future of Medicine: A Comprehensive Chain Innovation from Precision Therapy to Bionic Devices

2026-02-03

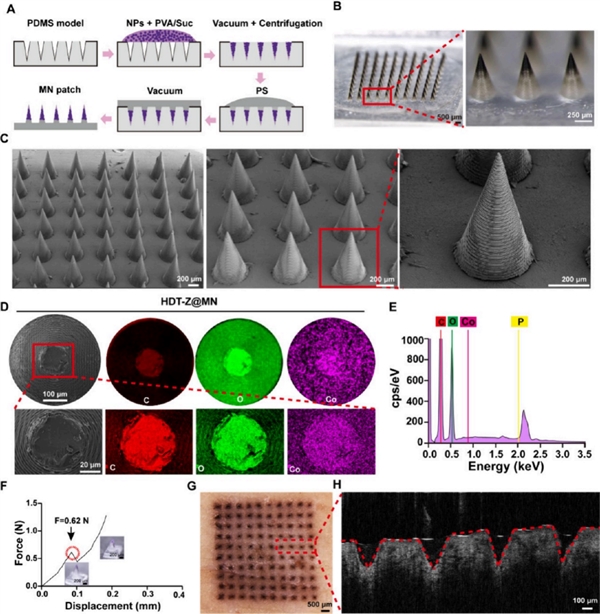

ACS Nano: Microneedle Scalpels Break the Deadlock of Breast Cancer Drug Resistance

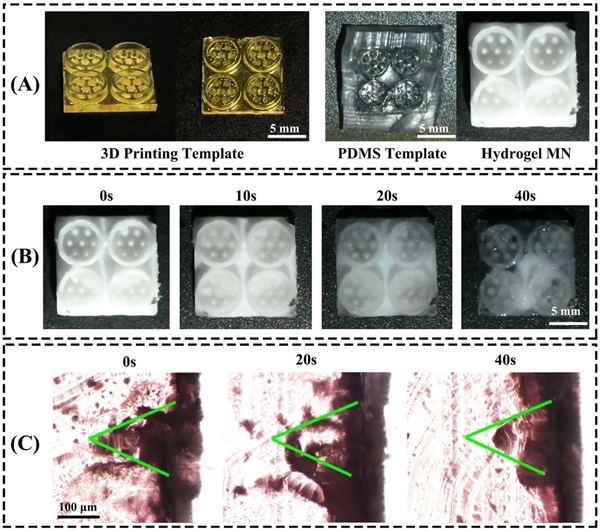

Advanced Science: Drosophila-Bionic Microneedle Patches for Efficient Therapeutic Efficacy

Chemical Engineering Journal: Mesen Sphere Bandages Accelerate Wound Healing

Keywords:

Related News

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262