NEWS EVENTS

Speed Empowerment! Analysis of Printing Speed of Our Three Types of Wax 3D Printers, Precisely Adapting to High-Efficiency Production Needs

2026-02-09

In the field of industrial-grade wax 3D printing, printing speed directly determines the production cycle, production efficiency and market response speed, and is the core empowerment point for large-scale production. Deeply rooted in the industry, our company accurately matches different speed and production capacity needs, and deploys three types of wax 3D printers: UR, DLP and LCD. Among them, the UR series stands out with extreme printing speed, whose printing speed can reach more than twice that of the DLP series and more than three times that of the LCD series. The three types of printers have their own focuses and complementary advantages, which not only cover diverse production scenarios, but also meet the core needs of different customers. The following will focus on the key word of printing speed, analyze combined with the core characteristics of each model, and provide clear selection references for various customers.

I. Speed Analysis of Three Types of Wax 3D Printers: Each Has Its Own Positioning, Highlighting Extreme Speed Efficiency

All three types of wax 3D printers adhere to the bottom line of high-quality forming, and the core differences focus on printing speed and applicable scenarios. Among them, the UR series focuses on "extreme speed and high efficiency", the DLP series focuses on "medium speed and precision", and the LCD series focuses on "precision adaptation". The specific analysis is as follows, focusing on the core advantages of printing speed of each series:

1. UR Series Wax 3D Printers: Leading in Extreme Speed, Doubling Efficiency (4KL110UR, 4KL150UR, 4KL200UR, 4KL250UR)

As the benchmark series for high-speed printing of our company, the UR series includes four models: 4KL110UR, 4KL150UR, 4KL200UR and 4KL250UR. All four models have the core advantage that "the printing speed is more than twice that of the DLP series and more than three times that of the LCD series", which completely breaks the dilemma of "high efficiency and quality cannot be achieved at the same time" of traditional wax 3D printers, and realizes the dual balance of extreme speed printing and high-quality forming.

|  |  |  |

On the basis of extreme speed, the four models continue their respective exclusive highlights and accurately adapt to different scenarios: the 4KL110UR model is compact and flexible, balancing high precision while achieving extreme speed printing, suitable for the rapid batch production of small precision parts; the 4KL150UR is characterized by "extreme smoothness", requiring no subsequent polishing after extreme speed printing, suitable for the efficient mass production of high-end small parts (such as fine jewelry); the 4KL200UR focuses on efficient mass production, equipped with a user-friendly operation design, to quickly respond to the needs of medium and large-scale batch orders; the 4KL250UR takes "super large forming size" as its core, realizing the integrated forming of large and complex wax molds without splitting and splicing under the premise of maintaining extreme speed printing, greatly shortening the production cycle of large parts, and truly achieving "fast production of large parts and rapid production of small parts".

The UR series is generally suitable for large-scale and high-efficiency production needs. Whether it is batch production of small parts or rapid forming of large parts, it can help enterprises shorten the production cycle, improve production capacity, reduce time costs and enhance market response capabilities with a speed far exceeding that of the DLP and LCD series.

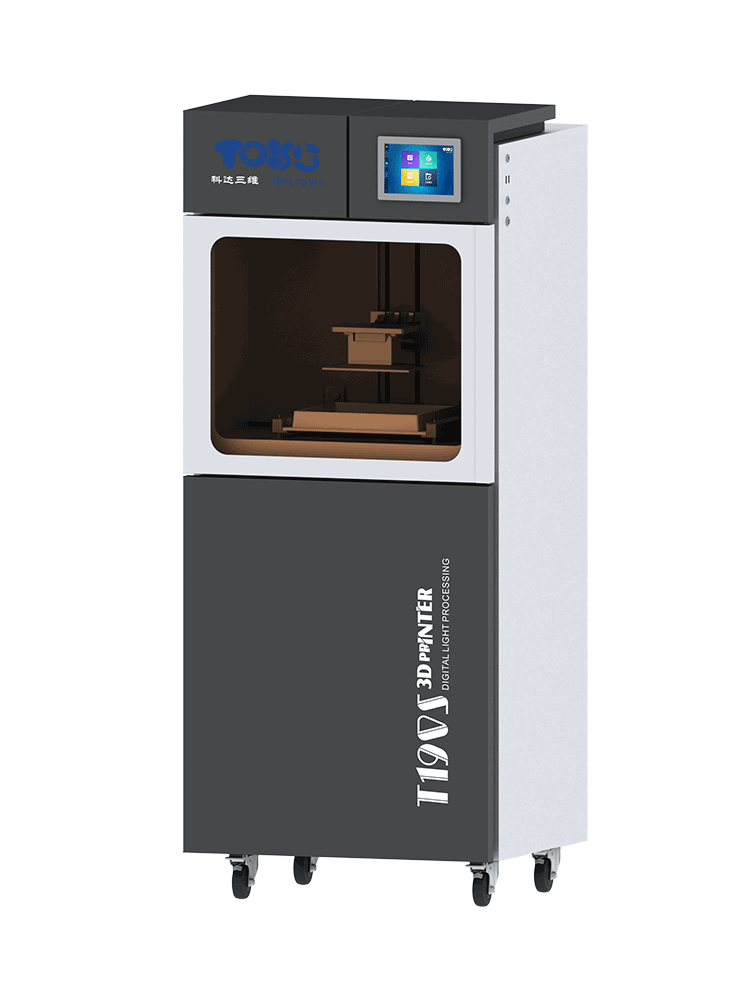

2. DLP Series Wax 3D Printers: Medium Speed and Stability, Precision Adaptation (T300H, T400G)

The DLP series includes two models: T300H and T400G, with moderate printing speed. Although it is not as fast as the UR series (only less than 1/2 of the UR series), it has the core advantages of high stability and high forming precision, suitable for production scenarios that require moderate printing speed and focus on forming precision and consistency.

|  |

Among them, the T300H model is suitable for the production of small and medium-sized batch precision wax molds, with stable printing speed and high light uniformity, which can accurately restore complex details, suitable for precision casting, small cultural and creative and other scenarios; the T400G model focuses on medium batch production, balancing precision and stability, with convenient operation, suitable for small and medium-sized enterprises that do not have extreme requirements on speed and focus on product quality consistency, which can meet daily batch production needs with outstanding cost performance.

3. LCD Series Wax 3D Printers: Precision and Efficiency, Adapting to Diverse Small Parts (C220, D300)

The LCD series includes two models: C220 and D300, with relatively slow printing speed, only less than 1/3 of the UR series. However, it has the advantages of moderate equipment cost, high forming precision and convenient operation, accurately adapting to the production scenarios of small-batch, high-precision small wax molds, without the need to pursue extreme speed, and focusing more on cost control and detail restoration.

|  |

The C220 model is compact and convenient, suitable for small workshops and start-up enterprises, which can quickly complete small-batch customized orders, balancing precision and cost; the D300 model is suitable for the production of small precision parts and simple jewelry wax molds, with stable printing and high detail restoration, suitable for customers who do not have high requirements on production speed and focus on low cost and precision, meeting the needs of personalized and small-batch production.

II. Overview of Core Speed Parameters: Quickly Lock in the Suitable Model

To facilitate the quick distinction of the speed differences among the three types of models, combined with the core positioning of each model, the core information related to speed is sorted out for overview, focusing on the key points of selection, helping customers quickly match their needs:

UR Series (4KL110UR/4KL150UR/4KL200UR/4KL250UR): Printing Speed → More than twice that of DLP series and more than three times that of LCD series; Core Advantages → Extreme speed and high efficiency, each model has its own exclusive highlights (smoothness, super large size, etc.); Applicable Scenarios → Large-scale, high-efficiency, multi-size production.

DLP Series (T300H/T400G): Printing Speed → Less than 1/2 of UR series; Core Advantages → Medium speed and stability, high precision; Applicable Scenarios → Medium-batch, high-precision production, no extreme requirements on speed.

LCD Series (C220/D300): Printing Speed → Less than 1/3 of UR series; Core Advantages → Low cost, high precision, convenient operation; Applicable Scenarios → Small-batch, personalized, low-cost small parts production.

III. Precise Recommendation for Customer Groups: Select Models on Demand, Empower High-Efficiency Production

Combined with the printing speed, core advantages and applicable scenarios of the three types of models, precise selection suggestions are given for the production needs of different customer groups (focusing on speed and efficiency, focusing on medium speed and precision, focusing on low-cost small parts), helping customers quickly lock in the optimal model and realize the dual optimization of production capacity and cost:

1. Medium and Large-Sized Jewelry/Precision Casting/Cultural and Creative Enterprises (Focus on Large-Scale, Extreme Speed and Efficiency)

Recommended Model: UR Series (select specific models on demand) Recommendation Reason: The core demand of such customers is large-batch and high-efficiency production, focusing on the improvement of production cycle and production capacity. The printing speed of the UR series is more than twice that of the DLP series and more than three times that of the LCD series, which can greatly shorten the production cycle, improve batch production efficiency, and help enterprises quickly respond to large orders. Specific models can be selected according to segmented needs: choose 4KL150UR for small-part high-precision and smooth mass production; choose 4KL200UR for medium and large-scale batch rapid production; choose 4KL250UR for large-part integrated rapid production; choose 4KL110UR for small precision part rapid production, fully adapting to large-scale and high-efficiency production needs.

2. Small and Medium-Sized Manufacturing Enterprises/Workshops (Focus on Medium Speed, Stability and High Precision)

Recommended Model: DLP Series (T300H/T400G) Recommendation Reason: Such customers have moderate production scale and no extreme requirements on printing speed. Their core demands are forming precision, product consistency and cost performance. The medium speed and stability of the DLP series can be perfectly adapted. Although the speed is not as fast as that of the UR series, it can complete medium-batch production with moderate efficiency, while ensuring high-quality forming, balancing cost and quality. Choose T300H for small-part precision mass production; choose T400G for medium-batch stable production, adapting to daily production needs.

3. Small Workshops/Start-Up Enterprises (Focus on Low Cost, Small Batch and Precision)

Recommended Model: LCD Series (C220/D300) Recommendation Reason: Such customers have small initial production capacity needs. Their core demands are to control equipment and production costs, while ensuring the forming precision of small parts. There is no need to pursue extreme speed printing. Although the speed of the LCD series is relatively slow, the equipment cost is moderate and the operation is convenient, which can efficiently complete small-batch customized and personalized production orders, balancing precision and low cost. Choose C220 for extremely simple operation and small-batch customization; choose D300 for small precision part production, helping start-up enterprises and workshops control costs and develop steadily.

Extreme Speed Empowerment, Adapting to New Needs of Diverse Production

Extreme Speed Empowerment, Adapting to New Needs of Diverse Production

Our three types of wax 3D printers, UR, DLP and LCD, take printing speed as the core differentiated positioning, building a complete product matrix of "extreme speed and high efficiency, medium speed and stability, and precision adaptation". With printing speed far exceeding that of the DLP and LCD series, the UR series has become the core choice for large-scale and high-efficiency production, while taking into account the exclusive advantages of each model; the DLP and LCD series accurately match medium-speed and low-speed scenarios, meeting the cost and precision needs of different customers. Whether customers focus on extreme speed and efficiency, medium speed and precision, or low-cost small parts production, they can find a suitable model, helping enterprises break through the bottleneck of production efficiency, achieve efficient and high-quality production, and empower the upgrading of the high-end manufacturing industry.

Keywords:

Related News

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262