NEWS EVENTS

Unlocking the Potential of Jewelry DLP 3D Printers: A Guide for Innovators

2026-02-09

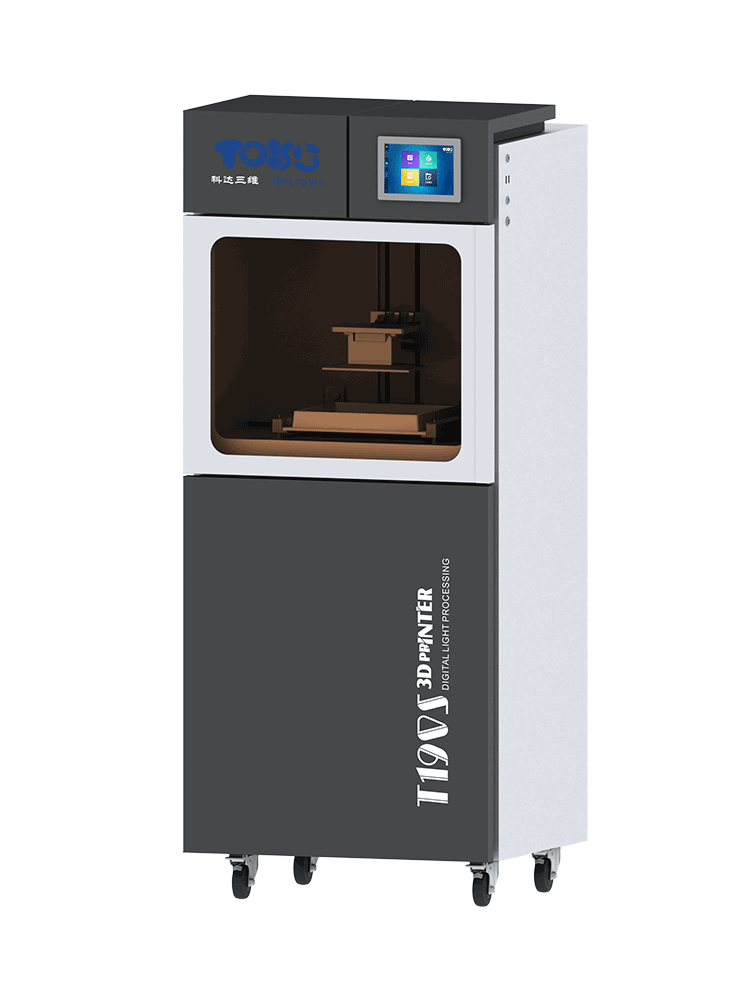

In today's rapidly evolving landscape of the jewelry industry, Jewelry DLP 3D Printers are emerging as game-changers. Utilizing Digital Light Processing (DLP) technology, these printers are designed specifically to create high-quality, detailed jewelry designs with precision and speed. This article delves into the unique benefits of Jewelry DLP 3D printers, illuminating how they can elevate your jewelry-making processes.

One of the standout features of Jewelry DLP 3D printers is their ability to produce intricate designs that were once difficult or impossible to achieve through traditional methods. The high resolution and clarity offered by DLP technology allow artisans to create detailed patterns, textures, and fine features that can significantly enhance the aesthetic appeal of their pieces. This capability not only fulfills the creative desires of jewelers but also meets the increasing consumer demand for unique, customized jewelry.

Moreover, the efficiency of Jewelry DLP 3D printers cannot be overlooked. These printers can produce multiple pieces simultaneously, drastically reducing the time required to bring designs from concept to reality. This efficiency is particularly beneficial in a market where speed is crucial to staying competitive. By streamlining the production process, jewelers can focus more on design innovation and less on time-consuming manufacturing tasks.

Additionally, the materials used in Jewelry DLP 3D printing are specifically formulated for durability and finish. This technology allows for the use of various resins that can mimic the appearance of metals and gemstones, providing a versatile range of design possibilities. Whether you are creating engagement rings, earrings, or custom pieces, the adaptability of these materials ensures that you can deliver high-quality products that meet your client's expectations.

Another significant advantage is the reduction of waste associated with traditional jewelry making. DLP printing is a subtractive process that uses only the necessary materials for each piece, minimizing excess. This eco-friendly approach not only appeals to environmentally conscious consumers but also aligns with the industry's growing emphasis on sustainability.

In conclusion, Jewelry DLP 3D printers offer a multitude of advantages that can redefine the jewelry-making landscape. From their ability to create intricate designs and enhance production efficiency to their use of versatile materials and commitment to sustainability, these printers are a valuable asset for jewelers looking to innovate and thrive in a competitive market. Embracing this technology can lead to new creative possibilities and a more streamlined production process, ultimately enriching the jewelry-making experience for artisans and consumers alike.

One of the standout features of Jewelry DLP 3D printers is their ability to produce intricate designs that were once difficult or impossible to achieve through traditional methods. The high resolution and clarity offered by DLP technology allow artisans to create detailed patterns, textures, and fine features that can significantly enhance the aesthetic appeal of their pieces. This capability not only fulfills the creative desires of jewelers but also meets the increasing consumer demand for unique, customized jewelry.

Moreover, the efficiency of Jewelry DLP 3D printers cannot be overlooked. These printers can produce multiple pieces simultaneously, drastically reducing the time required to bring designs from concept to reality. This efficiency is particularly beneficial in a market where speed is crucial to staying competitive. By streamlining the production process, jewelers can focus more on design innovation and less on time-consuming manufacturing tasks.

Additionally, the materials used in Jewelry DLP 3D printing are specifically formulated for durability and finish. This technology allows for the use of various resins that can mimic the appearance of metals and gemstones, providing a versatile range of design possibilities. Whether you are creating engagement rings, earrings, or custom pieces, the adaptability of these materials ensures that you can deliver high-quality products that meet your client's expectations.

Another significant advantage is the reduction of waste associated with traditional jewelry making. DLP printing is a subtractive process that uses only the necessary materials for each piece, minimizing excess. This eco-friendly approach not only appeals to environmentally conscious consumers but also aligns with the industry's growing emphasis on sustainability.

In conclusion, Jewelry DLP 3D printers offer a multitude of advantages that can redefine the jewelry-making landscape. From their ability to create intricate designs and enhance production efficiency to their use of versatile materials and commitment to sustainability, these printers are a valuable asset for jewelers looking to innovate and thrive in a competitive market. Embracing this technology can lead to new creative possibilities and a more streamlined production process, ultimately enriching the jewelry-making experience for artisans and consumers alike.

Keywords: Jewelry DLP 3D Printer

Related News

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262