NEWS EVENTS

Technical Details: 3D Printing Solution for Molding in the Precision Casting Industry

2026-02-10

The process of precision casting

The advantages of precision casting technology

【Fast】High speed and low cost. Within 2-3 days, disappearing molds can be obtained, meeting the business needs of multiple varieties and small batches.

【Excellent】It can print out wax molds with complex spatial structures, with a size accuracy close to that of the mold-punched wax molds.

【Clean】Only 0.05% ash residue remains, without any heavy metal elements, and it does not contaminate the castings.

The surface quality of the precision mold is excellent, with strong detail representation capability. After processing, the surface roughness can reach Ra1.6, and the minimum printing size is only 0.3mm.

When is SLA rapid precision casting required?

● Process Design Optimization

● Urgent Delivery Date

● In small quantities (less than 50 pieces), when the cost of making molds is high

●The structure is particularly complex and cannot be molded.

● Test pieces and prototype verification

Analysis of the Detailed Process of Casting Technology

1. Mold Manufacturing

The shell-cutting function of the pre-processing software transforms the mold into a hollow structure: This significantly reduces the consumption of resin raw materials, saving a considerable amount of costs; it basically eliminates the expansion problem of the resin during the later processing stage; and it greatly reduces the amount of ash residue left from the mold removal process.

● 3D printing for mold production: Regardless of the complexity, molds can be quickly produced. This eliminates the mold-making process, saving a significant amount of time and cost.

● Required software: Liantech Polydevs pre-processing software

The pre-processing software of Polydevs can customize the thickness of the shell removal, the length and width of the internal support arms, and freely select the position to place the discharge holes during data processing. The lightweight processing avoids the problem of shell expansion during degreasing.

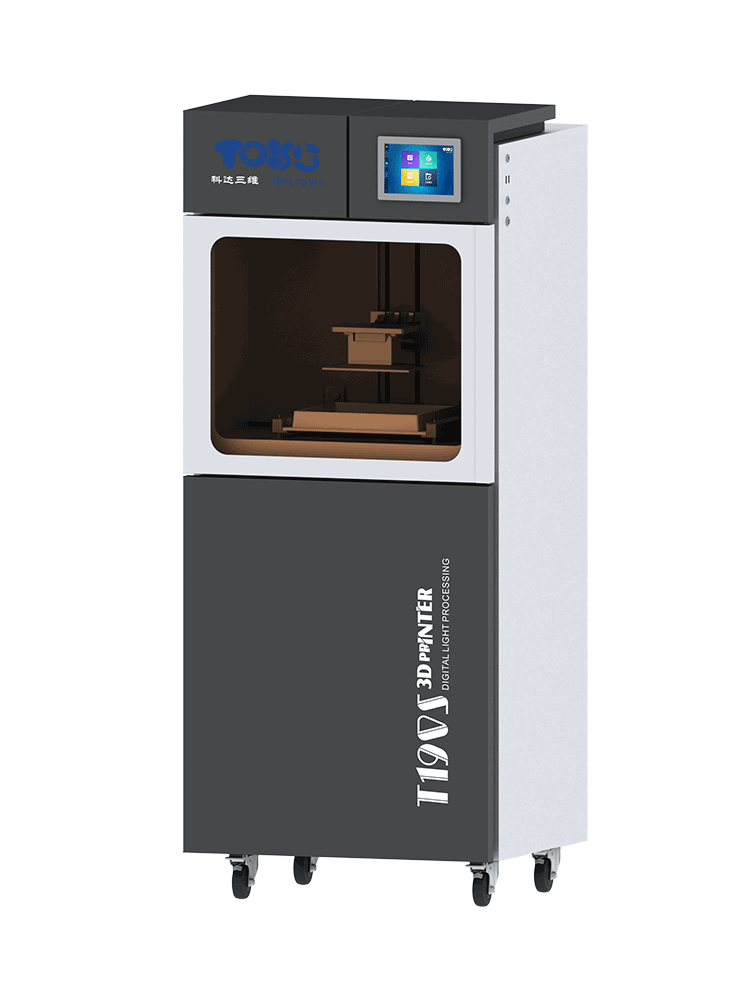

● Required equipment: Liantech SLA equipment Lite60

● Materials: Somos Photo-sensitive Resin 111222, Element

It has an extremely low ash content. Moreover, the ash content of the product is very easy to be cleaned. At the same time, it features low viscosity, stable size, smooth surface of components, easy surface treatment, and stable product.

II. Mold Preprocessing and Assembly Group Tree

The molds printed by SLA can be directly "welded" onto the riser using wax, and can be assembled in the same way as normal wax molds.

Considering the method of removing the SLA molds, the design of the riser and the flow channel can be larger than those of traditional wax molds, which helps air enter and facilitate the burning of the molds.

III. Shell Making

Before applying the first layer of slurry, pay attention to observing if any bubbles appear when cleaning the wax tree. If there are bubbles, it indicates that the mold seal is not good. When the wax tree is immersed in the slurry, avoid the buoyancy causing damage to the wax tree. To enhance the strength of the shell, consider adding an extra layer of shell or using reinforcement.

IV. Wax Removal

Before the firing process, the ventilation holes are heated through. This facilitates the gas convection during the firing.

V. Roasting

Subject to sufficient air supply and high-temperature baking, maintain the temperature at 800 - 1100 degrees for two hours (depending on the size of the part, extend the time appropriately)

The Somos casting-specific resin used in the SLA prototype (Somos@11122, Somos@Element) begins to soften at 50-60℃. Once the temperature exceeds 300℃, the molecular structure of the resin begins to collapse. At 600℃, the resin material burns and decomposes into carbon dioxide, water, and a small amount of residue. The temperature at which it completely burns out is around 800℃.

Six. Remove the ashes

The residue of impurities will affect the surface quality of the castings and cause internal defects.

VII. Preheating and Pouring

Before preheating, block the ventilation holes with ceramic rods, refractory mud, etc.

Finished product presentation

The application of 3D printing technology in the precision casting process is one of the important directions for the technological development of the precision casting industry. By combining the respective advantages of 3D printing and precision casting, it is possible to overcome the existing industry pain points such as high cost of small-batch mold production and large limitations of mold design. Currently, the application of 3D printing technology in production has become a trend in the precision casting industry. Whether it is the application of 3D printing wax molds, 3D printing ceramic cores, or 3D printing master molds, these applications will greatly enhance the market competitiveness of precision casting companies.

Disclaimer: This news information is sourced from the internet. If there is any infringement, please contact us for removal. cn@totustec.com

Keywords:

Related News

F2 Building 6A Jintong National Industrial Park No.8 Xihu Road Wujin District Changzhou City Jiangsu Province China

Follow Us

Copyright © 2022 Jiangsu Totustec. All Rights Reserved. 苏ICP备17013684号-1 Powered by:www.300.cn SEO

Online Message

Message

Message  cn@totustec.com

cn@totustec.com +86 18112582262

+86 18112582262